Technical specifications:

- Using by touch screen display

- Measures in opening and closing directions

- Measuring range: 00.00 to 99.00 Kgf.cm

- 3 measuring cycles (constant reading, Opening or Closing, Removal +Breaking)

- Units: Kgf.cm / N.m / Inch.lbs / N.cm

- Rotating speed adjustable

- Accuracy: ± 0.5 % of full scale

- 30 products memorization

- 10 thresholds (limits) option

- 10 operators memorization

- Configuration by protected password (administrator)

- Memorization up to 9999 measures (transferable)

- Dynamic display: statistics / hour / date

- Display: product name / operator / batch N° / Sample N°

- 1 USB output and 1 printer output (software & printer)

- Language: English

- Delivered with calibration certificate COFRAC

- 110 / 230 V – 50/60 Hz

- Automatic zero before restarting cycle

- Settable height of column for all samples

- Easy-fast selector for cycles

- Settable speed for screwing and unscrewing operations

- Stainless steel Frame

- Choice of jaw, or bottle neck clamp

- Dimensions: 350 x 590 x 950 mm

- Weight: 50 kg

Technical specifications: CFR21-11 / FDA compatible

- Free operator torque controller ( on-line )

- Legal weighing control suitable in option

- Secure seal test suitable ( automatic bubble point control )

- Using by touch screen

- Measures in opening and closing directions

- Measuring range: 00.00 to 99.00 Kgf.cm

- 6 measuring cycles: Torque closing / Reach position / Release + break / Release + break + over screw / Non-destructive test /– MORE ON REQUEST

- Units: Kgf.cm / Inch.lbs / daN.cm / N.cm / N.m

- Rotating angle & speed adjustable under certain cycle

- Accuracy: ± 0.5 % of full scale

- 30 products memory

- 10 thresholds (limits) option

- 10 operators memory

- Configuration by protected password (administrator)

- Memorization up to 9999 measures

- Dynamic display: statistics / hour / date

- Display: product name / operator / batch N° / line N°

- 1 RS232 output and 1 printer output (software & printer)

- Language: English / French / Spanish

- Delivered with calibration certificate ASTM/ NIST/COFRAC/ DKD ENAC / UKAS

- Easy-fast selector for cycles

- Customized cycles

- Special pneumatic chuck available

- Auto-mode

- Special auto mode with head number – filler storage

- Special multi format system for both bottle and preform

- Dynamometric system

- 110 / 230 V – 50/60 Hz

- Safety door

- Automatic zero before restarting cycle

- Settable height of column for all samples

- Stainless steel Frame

- Choice of measuring chucks: Beverage / Cosmetic / Pharmacy

- Dimensions: 1090 (L) x 710 (W) x 1120 (H) mm

- Weight: 120 kg

Technical specifications:

- Using by touch screen display

- Measures in opening and closing directions

- Measuring range: 00.00 to 99.00 Kgf.cm

- 6 measuring cycles: Torque closing / Reach position / Release + break / Release + break + over screw / Non-destructive test / Cork extraction test

- Units: Kgf.cm / N.m / Inch.lbs

- Rotating angle & speed adjustable under certain cycle

- Accuracy: ± 0.5 % of full scale

- 30 products memorization

- 10 thresholds (limits) option

- 10 operators memorization

- Configuration by protected password (administrator)

- Memorization up to 9999 measures (transferable)

- Dynamic display: statistics / hour / date

- Display: product name / operator / batch N° / line N°

- 1 RS232 output and 1 printer output (software & printer)

- Language: English

- Delivered with calibration certificate COFRAC

- 110 / 230 V – 50/60 Hz

- Safety door

- Automatic zero before restarting cycle

- Settable height of column for all samples

- Easy-fast selector for cycles

- Settable speed for opening and closing operations

- Customized cycles

- Special pneumatic chuck available

- Special multi format system for both bottle and preforms

- Dynamometric system

- Stainless steel Frame

- Choice of measuring chucks: Beverage / Cosmetic / Pharmacy

- Dimensions: 610 (L) x 570 (W) x 1080 (H) mm

- Weight: 94 kg

DESIGNED TO BE INSTALLED UNDER CAPPING HEADS

Our torque meters are designed with a special mechanical system for measuring torque which cancels most non- coaxial and top load influences on the measurement. These features cancel most operator influences on the measurement for maximum repeatability.

Technical specifications:

- Touch screen display

- Measurements in opening and closing directions

- Measuring range: 00.00 to 99.00 Kgf.cm

- 3 measuring modes (mean, peak, peak+info)

- Units: Kgf.cm / Inch.lbs / daN.cm / N.m / N.cm

- Accuracy: ± 0,2 % of full scale

- 50 product memory with 4 limits each

- 4 thresholds by product (Low, v Low, High, v High)

- 15 operator memory

- Setting of files by administrator code

- Store and transfer up to 1000 measurements

- Message + bar-graf f(x) of torque value

- Dynamic display: statistics, hour, date

- Display: product name, operator, batch N°, line N°

- 2 RS USB output (PC – printer)

- Language: French, Italian, Spanish, English, German

- Delivered with calibration certificate COFRAC

- 110 / 230 V – 50/60 Hz

- Stainless steel frame / IP 64

- Choice of measuring table: Food/Cosmetic/Pharmacy

- Optional battery

- Dimensions: Customize

- Weight: 7 kg

DESIGNED TO BE INSTALLED UNDER CAPPING HEAD – SCREW CAP -PILFER PROOF – SECURE CHILD

Our dynamometers include a special mechanical design permitting to avoid all influence from non-coaxial efforts. Also built-in a high speed electronic reading of measurements.

Mechanical specifications:

- Designed on request according to customers’ drawings

- Built-in battery 20H

- Dimensions: diameter mini: 50 mm / height: 104mm

- Weight 3 kg

- Ready to be installed on line after filling machine

- Enables to control capping heads in real conditions (speed and top load)

- No more dismantling!!

- Interchangeable formats

DESIGNED TO BE INSTALLED UNDER CAPPING HEAD – SCREW CAP -PILFER PROOF – SECURE CHILD

AT2E’s BT ETA FORCE includes a special mechanical design permitting to avoid all influence from non-coaxial efforts. It’s also built in a high speed electronic reading of measurements. Device can be custom-made according to different bottle or can profile. Using with our BT ETA Measure software, it’s very convenient for users to save, manage and analyse the data.

Mechanical specifications:

- Designed on request according to customers’ drawings

- Built-in battery 3H

- Dimensions: Customized

- Size range: Minimum diameter 35 mm / Minimum height 60mm

- Weight 1-2 kg

- Ready to be installed on line after filling machine

- Enables to control capping heads in real conditions (speed and top load)

- Interchangeable formats

Our Torque meters are designed with a special mechanical system for measuring torque which cancels most non- coaxial and top load influences on the measurement. These features cancel most operator influences on the measurement for maximum repeatability.

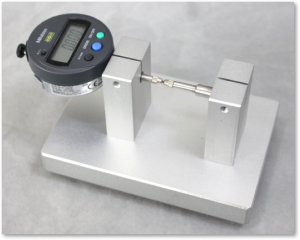

The new AT2E BT ETA TORQUE ECO has been developed in order to allow operators and calibration team to check in a fast way the accuracy of any torque testers.

Easy to use, just install the BT ETA TORQUE BOTTLE on the torque tester’s measurement table and turn slowly and smoothly in opening or closing direction.

Then just compare the value on your equipment to the BT ETA TORQUE ECO torques setting

Technical specifications:

- Adjustable torque from 1 to 15 Kgf.cm / Inch.lbs

- Measurements in opening and closing directions

- Delivered with calibration certificate (Option)

- No battery needed

- Transport case

- Aluminium made (Stainless steel on request)

- Dimensions: Customize

- Weight: 1- 4 kg

DESIGNED TO BE INSTALLED UNDER CAPPING HEADS

AT2E’s BT ETA TORQUE is built in with special mechanism permitting to avoid top load influence on measurement. It’s also built in a high speed electronic reading of measurements. Device can be custom-made according to different bottle or can profile. Using with our BT ETA Measure software, it’s very convenient for users to save, manage and analyse the data.

Technical specifications:

- Digital display

- Measures in opening and closing directions

- Measuring range: 00.00 to 60.00 Kgf.cm

- 2 Measuring modes (continue, peak)

- Units: Kgf.cm / Inch.lbs / N.m / N.cm

- Accuracy: ± 0.5 % of full scale

- Loading by USB (PC)

- Delivered with COFRAC certificate

- Transport case

- 110 / 230 V – 50/60 Hz

- Save up to 24 groups of data or 120 seconds of

- Designed on request regarding customers’ drawings

- Built-in battery 3H

- Dimensions: Customized

- Size range: Minimum diameter 35 mm / Minimum height 60mm

- Weight: 1-2 kg

The BTLT-1 is an instrument for testing the resistance to Top load effort on glass containers. It has been widely used by the glass container manufacturers and users. As a standard testing instrument for the glass container industry, it offers an important technical reference to the manufacturers for maintaining or improving the product quality and performance.

Designed for easy operation and maintenance, comply with the testing standard of ISO 8113:2004.

The top load test of containers is made up to a predefined pressure point (trial test) or until destruction.

Characteristics:

- User defined test cycle (up to 4 steps of pressure and holding time) satisfies different test request

- PLC integrated & Touch screen control

- Easy operation

- Can store 10 operators and 30 products

- User define the product lot number and sequence number

- Reviews the real-time testing curve

- Custom-made inserts for different types of samples, easier for sample installation and more accurate on pressure point.

- Lifting platform height adjustable accordingly to samples

- Lifting platform speed adjustable

- AT2E Patented trash bin design, more safety for operating and easier for scrap cleaning

- Maximum top load pressure up to 2200 Kgf / 22000 N

- Stainless steel frame and aluminum parts, more sturdy and durable.

- Overload protection

- Advanced safe door design ensures the safety of operator during a test.

- RS232 output interface, can be connected to printer or data acquisition software

- Measure range: 0 – 22000 N

- Units: KN / Kgf

- Resolution: 1 N

- Power: 220 V, 50-60 Hz

- Dimension: 610 (L) x 450 (W) x 870 (H) mm

- Weight: 80 kg

CET-1 Cork Extraction Tester is a force test system. It has been designed for wine producer and cork manufacturing industries. Easy to use, it allows to measure cork extraction or insertion and permits to improve the cork products and assembly/sealing process.

CET-1 ensures a repeatedly and accurate measure to check the push-in or pull-off force necessary to insert or extract the cork from bottles.

This is a standard test to ensure the Cork manufacturer or wine producer to let the end consumer open easily the bottle. It also allows to maintain the wine quality.

Operating:

- Insert the corkscrew into the cork.

- Install the bottle into the adapted support.

- Hook the extractor into the corkscrew.

- Apply a linear tensile action to the cork.

- Release the cork from the bottle, while the bottle is hold firmly.

- Maximum pull out/ push in force displays on the force gauge.

- Robust and reproducible tester

- Handle allows an easy operation

- Bottles range: (75cl, 50cl).

- Column with height adjustment

- Linear guide ensures axial guidage

- Calibration certificate

- Capacity : 100, 200, 500N

- Accuracy : 0.25% FS

- Resolution : 0.1 N

- Speed rate : 1000 Hz

- Linear guide ensures axial guidage

- Available : Digital or analog gauge

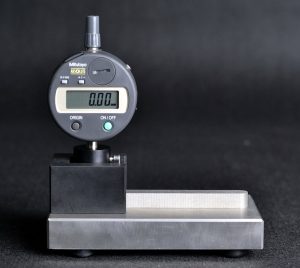

CG-D Countersink Gauge is a digital gauge for measuring countersink depth of can and end. For fast and easy measurement, the zeroization base is equipped.

In order to avoid the manual recording error, the gauge can be connected to “SPC” system or AT2E “SeamCheck” software with DTB-1 Data Transporting Box and cable. So that, the data can be transferred to “SPC” system or “SeamCheck” software through DTB-1 and cable.

Spécifications techniques :

- Measuring range 0-12 mm

- Resolution: 0.01 mm

- Accuracy: ±0.01 mm

- Sample range: 3-pcs & 2-pcs

- Overall size: 147(L) x 81(l) x 153(H) mm

- Net weight: 1 kg

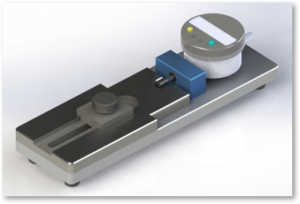

The CIDG-1 Can Internal Diameter Gauge is for quick checking the internal diameter of necked-in cans. For each diameter, a corresponding calibration block will be supplied along with the gauge.

It can be custom made to compatible for different can sizes in one gauge. Please specify when inquiring.

Technical specifications:

- Sample range: 2-pcs can and 3-pcs can

- Resolution: 0.01 mm

- Accuracy: ± 0.01 mm

- Dimension: 282(L) x 120(W) x 90(H) mm

- Net Weight: 5 kg (including calibration rings)

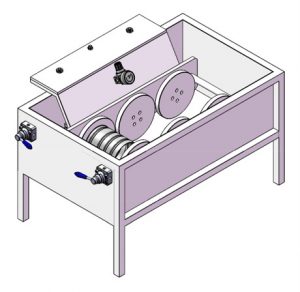

CLA-ECO Can Leak Analyzer is specifically designed for analyzing the secure seal ability of the empty 3-pieces tinplate cans. Water bath design with free rotating can holders allows a 360° observation on the can body (especially welding position) for air bubbles. It also ensures no defect spot can be missed and provides reliable test result.

Features:

- Pneumatic design which allows the tester be free from electricity

- Stainless steel water bath

- Semi-automated immersion

- Multiple testing positions (please consult AT2E for different position request)

- Applicable for most sizes of 3-pcs can

- Easy installation of samples

CO2-CS Automatic CO2 Calculating System is an innovative and full automatic CO2 content calculating system which is newly developed by AT2E. With the innovative shaking system and design, it will be safer for operator. Integrate touching screen design offers a user friendly operating process and abundant measuring information.

Features:

- Full automatic system – easy to get the CO2 content only by putting the sample into the system and the whole process including puncture, sealing, shaking, displaying and venting will be carried out automatically.

- Stainless steel design – which is more durable and steady when testing.

- Innovative shaking method – Allow the shaking of sample and the CO2 evolution to be more complete. Thus, the measure result will be more accurate. Meanwhile, with the innovative design, it avoids any mechanical maintenance problems which may occur on typical rotary shaker.

- Safety design – the whole shaking process is carried out inside the chamber which may avoid the potential danger to operator.

- PLC & Touch screen is equipped – which enable the more accurate measure and customized measure request. Shaking time and shaking speed can be set according to operator’s demand.

- Abundant information – operator, product name, batch number and sample number can be edited and saved with the system.

- 2 formulas – for alcohol drink and soft drink, 2 different CO2 calculating formulas could be selected as per demand.

- Threshold display – results which are higher and lower than the standard will be displayed.

- SPC connected is available.

- Easy clean for leftover drink in shaking system.

- Power supply: 230V/50Hz

- Sample range: up to 120mm in diameter / up to 360mm in height.

- CO2 measuring range: 0 – 9.99 g/L.

- Temperature measuring range: -10 to 60 °C

- Pressure measuring range: 0 – 6 bar.

- Accuracy: ±0.01 g/L (CO2), ±0.1 °C (temperature), ±0.01 bar (pressure).

- CO2 content units: “g/L”, “Volume”, “Weight%” and “P20[kg/cm2]”.

- Temperature units: °F and °C

- Language: English / French / Spanish / Chinese.

- Overall size (L x W x H): 104x54x106 cm.

- Net weight: 100 kg.

- Insert for different size of bottle

- Calibration pack

The CO2-P CO2 Purity Tester is a special instrument which is for calculating the purity of CO2. The principle is based on absorption burette to measure the impurities (O2 and N2 e.g.) of CO2 in a mixture of gases.

The CO2-P CO2 Purity Tester is widely used in breweries, the laboratory measurement of CO2 recycling and purchasing.

Technical specifications:

- Measurement range: 99.0~99.999% v/v CO2

- Accuracy:

- 00%~99.75%: 0.05 % v/v

- 80%~99.97%: 0.01 % v/v

- 980%~99.999%: 0.001 % v/v

- Volume: 105ml KOH (NaOH)

- Dimensions: 250mm×250mm×80mm

- Weight: about 0.75kg

- Alkali liquor: 30% g/v KOH (NaOH)

AT2E CO2DA – Automatic Shaker & CO2 Calculator is a special instrument which is for calculating the carbon dioxide content in the filled drink in glass/PET bottles and cans. The simple operation which also guarantees high reproducibility makes it become a significant equipment of quality control in the beverage industry.

Operation:

- Place the sample drink

- Piercing the sample

- Press the start button to test

- Obtain the carbon dioxide content after shaking

- Instead of manual shaking, motor shaking guarantees high reproducibility

- Stainless steel design

- High resolution touch screen with user-friendly interface

- Settable shaking speed and time

- High accuracy

- Calculate the CO2 content automatically and rapidly

- Good repeatability

- Simple and easy piercing & operation

- Applicable for most of the glass bottle, PET bottle and can

- Measuring range:

- CO2: 00 to 9.99 g/l

- Temperature: 0 to 60 °C

- Pressure: 0 to 6 bar

- Accuracy:

- CO2: ±0.01 g/l

- Temperature: ±2 °C

- Pressure: ±0.02 bar

- Resolution:

- Temperature: 0.1 °C

- Pressure: 0.01 bar

- Sample range:

- Maximum diameter: 120 mm

- Maximum height: 380mm

- Units:

- CO2: g/L, Vol, %b.w, Kg/cm2

- Pressure: bar, psi

- Temperature: °C, °F

- Power supply: AC 220V / 50Hz

- Dimension: 580(L) x 380(W) x 365(H) mm

- Net weight: 30 kg

For a constant quality and taste of all kinds of carbonated drinks, the critical parameter is the CO2 (carbon dioxide) content in the liquid.

Our CO2 measuring device is a standard equipment and widely used in breweries and in the non-alcoholic beverage industry for frequent measuring of the CO2 content during production.

Allows a fast and accurate determination of the CO2 content in beer and carbonated drinks after drilling.

Technical specifications:

- Pressure units: Bar / MPa (dual graduation)

- Temperature units: °C

- Measuring range: 0 – 6 Bar

- Resolution: 0.1 Bar / 0.01 Bar

- Temperature: 0 – 50 °c

- Resolution: 0.1°C

- Sample height range: 50 mm – 330 mm

- Bottle diameter: maximum 90 mm

- Dimension: 140 (L) x 200 (W) x 430 (H) mm

- Net weight: 2 kg

Presentation:

This aphrometer is designed to check the pressure after the disgorging process of sparkling wines.

It measures the pressure in the champagne bottles topped on with a wire-hood and a cork.

Its strong mechanism allows it to pierce easily the wire-hood and the cork to check.

The cork ensures the airtightness during the test.

Advantages:

- Strong mechanism.

- Stainless steel manometer: (0/10) Bar.

- Quality made.

- Especially designed to pierce wire-hoods and corks

- Can be used for cider bottles topped on with a wire-hood and a cork.

Presentation:

This aphrometer is designed to check the pressure during the secondary fermentation.

This Champagne pressure gauge checks instantaneously the pressure in the bottles topped on with a crown cap with or without plastic shutter.

A gasket ensures the airtightness between the aphrometer and the crown cap.

Finish type available:

- Finish type: crown 26 mm

- Finish type: crown 29 mm

- Finish type: crown 36 mm (jeroboam)

- Finish type: screw cap

- Strong and reliable mechanism.

- Stainless steel Manometer: (0/10) Bar.

- Can check several batches.

- Customizable aphrometer.

- Quality made.

CSM Can Seam Micrometers is used for a quick measurement of seam thickness and seam length. It’s an easy-operated tool and widely use in canning industry.

Technical specifications:

- Measuring range: 0-13 mm

- Resolution: 0.001 mm

- Accuracy: ± 3µm

- Sample range: 3-pcs can & 2-pcs can & Aerosol can

- Net weight: 0,2 kg

Resistance to tensile or compression

DYNAMOMETER WITH AT2E MECHANIC

- Range: 20, 100, 200, 500N

- Please specify when ordering

- Measure tension and compression.

- Reading on the dial needle

- Zero Recalibration by a touch

- Accuracy: 0.1% of full scale

- Choice of unit: kgf. / N

- Storage case and tools (hooks, etc.)

- Weight: 560 g

- Dimensions: 230x60x50mm

- Supplied with calibration certificate and PV

ECDG-1 End Curl Diameter Gauge is for quick measure of the Curl Diameter of ends.

Easy-operation design offers a fast and accurate measurement of the Curl Diameter. For each end type, a corresponding calibration block will be supplied along with the gauge.

In order to avoid the manual recording error, the gauge can be connected to SPC system with DTB-1 Data Transporting Box and cable. So that, the data can be transferred to SPC system DTB-1 and cable.

Technical specifications:

- Measuring range: Φ50-Φ110 mm

- Resolution: 0.01 mm

- Accuracy: ±0.01 mm

- Sample End Type: 113# – 401# (larger by order)

- Overall size: 265(L) x 80(W) x 195(H) mm

- Net weight: 2 kg

Simple and useful measuring tool for fill height measurement. It’s designed for all size bottles. Gauge may be preset in inches or millimeters to check fill height level on production line or may be used to measure exact fill point of bottle and then compared to standard. Rule may be raised or lowered to compensate for the thickness of various crown caps.

Technical information

- Measuring range: 0 to 150 mm

- Graduation: mm / inch

The “FT-1 Fatigue Tester” is used to test and analyze the durability and quality of all packaging in compression or traction direction. It’s widely used in cosmetic, pharmaceutical and other industries.

It’s an automated tester and testing cycle is carried out by program. Testing process is as below:

- Select the testing direction (compression or traction direction)

- Place the sample under the force gauge

- Adjust the force gauge position by the top hand wheel

- Input the testing number of time

- Press the “START” button to start the test

- Observe the sample and analyze the force value after the test

- Full stainless steel & safety door design

- Ruler for sample adjusting

- Digital display of real-time or peak or average force value

- 3” LCD touching screen which offers a user-friendly interface for operation

- Test mode: compression or traction

- Choice of cylinder movement: both “manual” and “automatic” are available

- Equipped with data collection software for force value management

FWG-1 Flange Width Gauge is used to measure the flange width of empty cans.

Easy-operation design offers a fast and accurate measurement of flange width.

In order to avoid the manual recording error, the gauge can be connected to SPC system or AT2E “SeamCheck” software with DTB-1 Data Transporting Box and cable. So that, the data can be transferred to SPC system or “SeamCheck” software through DTB-1 and cable.

Spécifications techniques :

- Measuring range: 0-5 mm

- Resolution: 0.01 mm

- Accuracy: ±0.01 mm

- Sample range: 3-pcs & 2-pcs

- Sample capacity: 50 mm à 90 mm dia. can (Bigger by order)

- Overall size: 180(L) x 103(l) x 108(H) mm

- Net weight: 1 kg

Special instrument for testing the impact resistance ability of various glass bottles and jars.

Attribute

- The sample clamp is able to move flexibly on vertical or horizontal direction, convenient for adjusting the sample position.

- Instrument design accord with the law of the conservation of energy, ensured the testing accuracy and test reliability.

- Stable and accurate pendulum able to rotate and release freely.

- With stainless steel safety shield.

- User-friendly design, easier for operation.

- Sample diameter range: Ф20-130 mm (clamps for other range available)

- Max. impact energy: 2J

- Resolution : 0.1J for each lattice (when impact energy larger than 0.6J) 0.05J for each lattice (when impact energy less than 0.6J)

- Energy loss: ≤1.5% PE

- Dimensions: 530 x 350 x 700 mm

GDTB-4 Gauge Data Transportation Box is a data process box specially developed for collecting the data from Mitutoyo digital gauges. With the GDTB, users are able to collect the Mitutoyo digital gauges’ data and send to data acquisition system or AT2E’s “QUALIGAUGE” software. It is able to connect up to 4 gauges.

With GDTB-4 and “QUALIGAUGE” software, date can be transferred from any Mitutoyo digital gauges. User can review and manage all the saved data. Data report and graph are available with the “QUALIGAUGE” software which is very useful for data and result analyzing.

Technical specifications:

- Overall size: 140 x 105 x 55 mm

- Number of the ports for Mitutoyo gauge: 4 (Please consult AT2E for other request)

- Main supply: USB

- “QUALIGAUGE” software

This unit has an excellent basis for measuring. It’s easy to use. Crown cap height and thickness are measured by analog indicator. It is widely used in crown cap, brewery and beverage industries.

Technical specifications:

- Measuring range: 0 – 10mm

- Resolution: 0.01 mm

- Dimension: 100 (L) x 100 (W) x 160 (H) mm

- Net weight: 2 kg

The HWBC-1 Hot Wire Bottle Cutter offers an easy and cost saving way for cutting containers for section weight analysis. A clean section without deformation will be obtained by a quick cutting of bottles through heated hot wires. A precision and repeatable cutting task is easy to achieve and it’s necessary for a proper analysis.

With HWBC-1, a PET bottle could be cut up to 5 predetermined sections, each section will be checked to ensure that it conforms to the exact weight assigned.

Attributes:

- Bottle cut with accuracy

- Rapid warming the wires

- Energy saving design

- Up to 5 sections cut

- Durable design

- Easy to operate

- Cutting up to 2 L bottle

- Safety cover design which exhausts gases out of face of the operator (optional)

- Excellent repeatability

- Preheating Mode / Cut Mode (heating max)

AT2E innovative HWBC-2 Hot Wire Bottle Cutter offers an automated and cost saving way for cutting containers for section weight analysis. A clean section without deformation will be obtained by a quick cutting of bottles through heated hot wires. A precision and repeatable cutting task is easy to achieve and it’s necessary for a proper analysis.

With HWBC-2, an automatic and steady cutting process will be carried out after pressing the button. With exhaust fan and safety door design, the exhaust gas will be away from the operator during cutting.

With HWBC-2, a PET bottle could be cut up to 5 predetermined sections under a steady force and excellent section plane could be obtained. Each section will be checked to ensure that it conforms to the exact weight assigned.

Features:

- Automatic and accurate cutting process offers a very easy way of operation

- Heating power / Standby power / Cutting speed / Return speed of wire / Cutting delay are adjustable

- Energy saving design

- Durable stainless steel design

- Touching screen offers easy and user-friendly operation

- Up to 5 sections cut and suitable for up to 2 L bottle

- Safety door and exhaust fan design which exhausts gases away from the operator

- Excellent repeatability

- Adjustable supports for bottles during the cutting process

- Graduated rulers allow accurate positioning of wires

- Sample range:

- Maximum height360 mm

- Maximum diameter 110 mm

- Mains supply: 220 VAC / 50Hz

- Overall size: 500 (L) x 580 (W) x 600 (H) mm

- Net weight: 35 KG

The aim of this unit is to test whether the internal diameter of the tested sample is within standard or not.

- Judgment of reference: the small end must adapt to the internal circle of the samples, while the larger end should not adapt to the internal circle of the samples.

- It can be custom-made as different diameters.

Presentation:

This aphrometer checks the evolution of the pressure during the secondary fermentation.

Remove one bottle without cap from the filling machine and put the aphrometer on the bottleneck.

The permanent aphrometer will remain on the bottleneck during the entire secondary fermentation.

A gasket ensures the airtightness between the aphrometer and the bottleneck.

This aphrometer can be adapted to the following bottlenecks:

- Jeroboam.

- Special bottles.

- Checks the evolution of the pressure.

- Stainless steel manometer.

- Customizable aphrometer.

- Quality made.

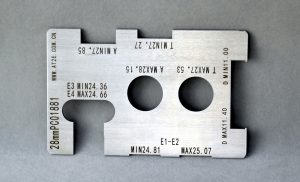

Quality control gauges for checking the threaded tops of glass and plastic containers. Check the threads, outside diameter, spacing, etc.

Comb. Finish Gauge 28mm-PCO-1816 PET

Comb. Finish Gauge 28mm Pet/28-969-1716

Comb. Finish Gauge 38mm Glass/38-1663

Comb. Finish Gauge 38mm Pet/38-1690

Comb. Finish Gauge 28mm Glass/28-1650RE

Comb. Finish Gauge 28mm-PCO-1810 PET

Comb. Finish Gauge 28BPF

Strength pull off cap tester

Features:

- Easy to use

- High repeatability in testing

- Built-in dynamometer with software

- Range: 50 / 200 / 1000 N (Please specify when ordering)

- Measure tensile & compressive strain

- Digital display and reversible

- Programming menu.

- Measurement Mode Continuous / Peak / PC Link

- Recalibration of the zero touch

- Accuracy: 0.05 N

- Display threshold (limit)

- Choice of unit: kgf. / Lbf / N

- Integrated battery with charge

- Data will be transferred to the software with curve

- Dimensions: 500 x 250 x 600 mm

- Net weight: 15 KG

The “PPG-A” and “PPG-D” are used to measure the perpendicularity (deviation) of the preform and it’s a standard equipment for PET and beverage industries.

With special designed changing & clamping part, it can ensure the accurate measurement of different sizes of preform.

Clamping support and calibration bar are corresponding to each diameter of preform opening. Please provide the detailed preform specification when ordering.

Technical specifications:

- Sample range: by order

- Resolution: 0.01 mm

- Dimension: 300 (L) x 250 (W) x 450 (H) mm

- Net weight: 15 kg

- Many typical laboratory functions have been expanded to include a clear graphics screen, which shows the relevant information visually and makes it significantly easier to operate and read the weights off the display

- Navigation pad for super quick navigation through the menus

- 40 memories for each mode

- Extensive print formats – up to 20 lines with fixed and variable texts

- High mobility: thanks to rechargeable battery operation (optional), compact, low weight construction, it is suitable for use in several locations (laboratory, production, quality testing, commissioning,…)

- Ring-shaped draft shield optional, weighing space ØxH 90×53 mm

- Hook for underfloor weighing to weigh hanging loads standard

- Capacity display

- Dispensing assistance (subtractive, additive)

- Piece counting with reference

- Automatic reference optimisation

- Tare deduction from the memory unit

- Input of item or batch description, operator etc. from the memory unit

- Freely programmable weighing unit, e. g. display directly in special units such as length of thread g/m, paper weight g/m2, or similar

- Date/time in the display

- Individual printout configuration

PTG -1 Plate Thickness Gauge is for quick checking of the thickness of plates.

Easy-operation design offers a fast and accurate measurement of the plate thickness.

In order to avoid the manual recording error, the gauge can be connected to SPC system or AT2E “SeamCheck” software with DTB-1 Data Transporting Box and cable. So that, the data can be transferred

Technical specifications:

- Measuring range: 0-6 mm

- Resolution : 0.001 mm

- Accuracy: ±0.001 mm

- Overall size: 200(L) x 80(l) x 110(H) mm

- Net weight: 1 kg

The “PVG” is used to measure pressure or vacuum of can or bottle.

Simply place the sample under the entity manometer or vacuum meter and lower the lever. Then read the value.

Advantages:

- Easy to use

- Available with analog or digital indicator

- Different accuracy class

- Fits all samples

- Vacuum range:

- -1 to 0 bar / -14.5 to 0 psi (Analog)

- -100 to 0 kPa (Digital)

- Pressure range: 0 to 6 bar

- Resolution: on request

- Precision: 0.1% to 5% according to model

- Weight: 3 Kg

“PVG-P” is the portable model for measuring pressure or vacuum into bottle.

Install the PVG-P under the finish neck and adjust the needle on the cap’s center, then screw the nut.

The needle will pierce the cap without leakage and check the pressure or vacuum value.

Advantages:

- Easy to use

- Available with analog or digital indicator

- Different accuracy class

- Fits all samples

- Vacuum range:

- -1 to 0 bar / -14.5 to 0 psi (Analog)

- -100 to 0 kPa (Digital)

- Pressure range: 0 to 6 bar

- Resolution: on request

- Precision: 0.1% to 5% according to model

- Weight: 3 Kg

The AT2E SCT-D Stress Crack Tester is designed to test the internal stress in bottle base and for determining the stress crack resistance of blow-molded PET carbonated soft drink bottles by measuring the propensity for base cracking upon exposure to an aqueous sodium hydroxide solution under a controlled environment, so that to estimate the long term behavior of bottles.

As per the above screen shot, during the test, the bottles in #6 and #16 positions leak, the lights of positions #6 and #16 will become green automatically and system will stop pressurizing the corresponding positions.

Or, operator can press the position button to stop pressurizing if any tiny leakage occurs by observation. Leak pressure value and time will be displayed below the button.

System will also generate a data table for each test to record the test pressure of each position. In the table, position with green light will be displayed as “NG” with the leakage pressure value. Normal position will be displayed as “OK” with the predefined pressure value. The data table can also be printed out through the mini printer.

Attributes:

- Multi-position design, more convenient and efficient (Please consult AT2E for other position request).

- Automation control ensures the high accuracy and repeatability.

- High quality stainless steel frame which is safe and durable.

- Superior controlling components ensures the accuracy and durability.

- Flexible position selection – each position can be controlled separately by system. Users can enable the positions (from 1 to 26) according to their test request.

- Automatic pressure compensation during the test process.

- Suitable for testing various size of bottle.

- Corrosion-resistant design

- Anti-explosion and clear observation window which is safe and easy to observe the sample status during a test.

- Various safety designs.

The AT2E Stress Crack Tester is designed to test the internal stress in bottle base and for determining the stress crack resistance of blow-molded PET carbonated soft drink bottles by measuring the propensity for base cracking upon exposure to an aqueous sodium hydroxide solution under a controlled environment, so that to estimate the long term behavior of bottles.

Attributes:

- Muilt-position design, more convenient and efficient (Please consult AT2E for other position reqeust)

- PLC control ensures the high accuracy and reliability

- High quality stainless steel frame, more safe and duable

- Flexible position selection, each position can be controlled separately by system. Users can enable the positionsaccording to their test reqeust

- Automatic affusion system

- Auto pressure compensation during test process

- Suitable for testing various bottle size

- Corrosion-resistant design

- Anti-explosion and clear observation window, safe and easy to observe the sample status during tests

- Various safety design

Presentation:

The simplified Aphrometer is designed to check the pressure and the vacuum in the bottles of still wine (Bordeaux bottles, Burgundy bottles).

Thanks to its sting this pressure gauge pierces corks and some synthetic corks, but it cannot pierce crown caps or all other metallic shutters.

The cork ensures the airtightness.

Stainless steel Manometers available:

- (-1/+1,5) Bar (default manometer)

- (0/4) Bar

- (0/6) Bar

- 2 mm

- 2.5 mm

- 4 mm

- Reliable mechanism.

- Checks the pressure and the vacuum.

- Quality made.

- Can check several batches.

- Stainless steel manometer.

- Customizable aphrometer.

SLG-1 Seam Length Gauge is for quick measure of the Seam length (Seam height)

Easy-operation design offers a fast and accurate measurement of the Seam length (Seam height).

Reliable design, invariable measuring pressure and measuring angle which enable the operators perform the measurement accurately. The can body was aligned vertically, measurement results are more reliable. Applicable for different types of cans.

In order to avoid the manual recording error, the gauge can be connected to SPC system or AT2E “SeamCheck” software with DTB-1 Data Transporting Box and cable. So that, the data can be transferred to SPC system or “SeamCheck” software through DTB-1 and cable.

Technical specifications:

- Measuring range: 0-7 mm

- Resolution: 0.01 mm

- Accuracy: ±0.01 mm

- Sample range: 3-pcs & 2-pcs

- Overall size: 300(L) x 80(l) x 265(H) mm

- Net weight: 1 kg

STG-1 Seam thickness gauge is used to measure the Seam thickness of cans.

Easy-operation design offers a fast and accurate measurement of seam thickness.

With measure angle compensation and adjusted center measure point, the can could be auto-positioned in the center easily during measuring. The gauge is applicable for different kinds of cans.

When using the double seam projector, the seam structure may have a slight deformation after cut by the seaming cutting saw, the seam thickness measured on the projector therefore will have a certain deviation. While using the seam thickness gauge, it is able to measure the actual seam thickness value.

In order to avoid the manual recording error, the gauge can be connected to SPC system or AT2E “SeamCheck” software with DTB-1 Data Transporting Box and cable. So that, the data can be transferred to SPC system or “SeamCheck” software through DTB-1 and cable.

- Measuring range: 0-6 mm

- Resolution: 0.01 mm

- Accuracy: ±0.01 mm

- Sample range: 3-pcs & 2-pcs

- Sample capacity: 50 mm à 90 mm dia. can (Bigger by order)

- Overall size: 180(L) x 103(l) x 108(H) mm

- PoiNet weight: 1 kg

AT2E TCT-2 measure the resistance to tear or top load force (traction or compression) for all kind of packaging. Sample installed on the support and the force is raised in tear or top load direction gradually. The distance between the gauge and the support plate and column can be adjusted on request. The sample will be compressed or tore until the maximum force or respecting the settings of testing distance. The value is read on the touch screen and a report is printed.

TCT-2 complies with the ISBT voluntary standard test methods for PET bottles. With the user-defined test cycles, it can be widely compatible for any in-house standards from customers on different test requests.

Characteristic:

- Perfectly parallel plates

- Automatic record of the force

- Touch screen display

- Predefined the testing distance and testing speed

- Available for both compression (top load) test the traction (pull) test

- User-defined test cycle (up to 4 steps of force and holding time) satisfies different test request

- Memory of 30 products, 10 operators, batch number, sample number ( all by password )

- Easy installation of samples.

- Displays all the information during cycle: time, setting, operator, product, batch NO., Sample NO., value

- Reviews the real-time testing curve

- RS232 outputs

- Stainless steel design ensures the durability of tester

- Overload protected

- Safety design

- Dimensions: 500 x 400 x 870 mm

- Measuring range: 0-1000 N (Bigger by order)

- Resolution:1 N

- Power: 110/240 V, AC50-60 Hz

- Weight: 50 kg

Our torque tester are designed with a special mechanical system for measuring torque which cancels most non-coaxial and top load influences on the measurement. These features cancel most operator induced influences on the measurement for maximum repeatability.

Technical specifications:

- Touch screen display

- Measures opening and closing directions

- 0.080 to 4.000 Kgf.cm in high accuracy mode

- Measuring range: 00.00 to 99.00 Kgf.cm

- 3 measuring modes (mean, peak, peak+infos)

- Units: Kgf.cm / Inch.lbs / daN.cm / N.m / N.cm

- Accuracy: ± 0.5 % of full scale

- 100 product memory with 4 limits each

- 4 thresholds by product (V Low, Low, High, v High)

- 20 operators memory

- Setting of files by administrator code

- Store and transfer up to 999 measurements

- Message + bar graph of torque value

- Dynamic display: statistics, hour, date

- Display: product name, operator, batch N°, line N°

- 1 RS232 output for software & 1 printer output

- Language: French / Italian / Spanish / English

- Delivered with COFRAC calibration certificate

- 110 / 230 V – 50/60 Hz

- Stainless steel frame

- Choice of measuring table: Agro / Cosmetic

- Optional battery

- Dimensions: 300 (L) x 180 (W) x 200 (H) mm

- Weight: 7 kg

Technical specifications:

- 7″ Touch screen color display

- Measures opening and closing directions

- 0.030 to 4.000 Kgf.cm in high accuracy mode

- Measuring range: 00.00 to 99.00 Kgf.cm

- 3 measuring modes (mean, peak, peak+infos)

- Special mode RELEASING & BREAKING Torque

- Units: Kgf.cm / Inch.lbs / daN.cm / N.m / N.cm

- Accuracy: ± 0.2 % of full scale

- 30 product memory with 4 limits each

- 4 thresholds by product (V Low, Low, High, v High)

- 10 operators memory

- 8 Access levels with code (op, Super op, admin)

- Storage and transfer up to 9999 measurements

- Message + bar graph of torque value

- Dynamic display: statistics, hour, date

- Display: product name, operator, batch N°, line N°

- Last measure curve

- 2 outputs: RS232 & mini USB (software & printer)

- Language: French / Italian / Spanish / English

- Delivered with ASTM calibration certificate

- 110 / 230 V – 50/60 Hz

- Transportation case

- Stainless steel frame

- Choice of measuring table: Agro / Fast squeeze system

- Dimensions: 370 x 215 x150 to 200 mm

- Weight: 7 kg

Our torque meters are designed with a special mechanical system for measuring torque which cancels most non- coaxial and top load influences on the measurement. These features cancel most operator influences on the measurement for maximum repeatability.

The TORQUE CHECK has been developed in order to allow operators to control the torque, calibration team to check in a fast way the accuracy of any torque testers and maintenance to control and adjust torque directly on capping heads

Easy to use, just install TORQUE CHECK on the torque tester, on the cap or under the capping head and turn slowly and smoothly in opening or closing direction.

Technical specifications:

- Digital display

- Measures in opening and closing directions

- Measuring range: 00.00 to 60.00 Kgf.cm

- 2 Measuring modes (continue, peak)

- Units: Kgf.cm / Inch.lbs / N.m / N.cm

- Accuracy: ± 0.5 % of full scale

- measures memory with curves

- Loading / Transfer by USB (PC)

- Delivered with ASTM certificate

- Transport case

- 110 / 230 V – 50/60 Hz

- Designed on request regarding customers’ drawings

- Built-in battery 3H

- Size range: Minimum diameter 35 mm / Minimum height 60mm

- Weight: 0,5 kg

AT2E ER-1 Enamel Rater offers a fast and accurate method to measure the integrality of internal coating of containers. A measuring will be started automatically when the electrical probe is inserted and contacts the solution inside the container.

The position of exposed metal can be detected visually by pressing the “REVERSE” button. Bubbles of gas come out on the exposed points.

Measuring principle:

The instrument applies a constant micro-voltage across the can body and an electrode immersed in the electrolytic water filled, and measuring the resulting current. Voltage during the test is 6.3 V DC. The operating range is 0 to 300 milliampere with an accuracy of resolution of 0.01 milliampere.

The cover support comprises a container mounted on a pivot. The cup is beveled to make a tight seal on the can cover. An electrode and the connection to the vacuum in the container are mounted. On the base, a valve for creating a vacuum and a movable arm, complete the electrical circuit when the assembly is inverted.

Measuring modes:

- 4 second mode: The reading will be displayed only at 4 seconds.

- Continuous mode: The changing current reading will be displayed during all the measuring time. It will not stop displaying until operator’s order.

- User-defined mode: The reading will be displayed at the setting time by operator.

- Test the coverage of theenamel coatinginsidecanned food, beverages, tubes and aerosolsas well asthe different types of

- Displaysan index ofthe amount of metalexposed byincompleteenamelcoverage.

- Integrated 7” LCD touch screen and user friendly interface offers the easy-operation.

- Operator, product, sample & batch number can be memorized

- RS 232 output.

- Userself-

- Detect theexposed position of metal.

- Sample range: 2-pcs can, 3-pcs can, aerosol can, tube and differenttypes ofcovers

- Can sample capacity: by order

- End sample capacity: by order

- Measuring range: 0 to300 mA

- Resolution: 0.01mA

- Accuracy: ±5% F.S.

- Power supply:DC 12V

- Data output:RS232 serialoutput

- Main frame dimension:212(L) x185(W) x150(H) mm

- Can holder dimension: 200(L) x 235(W) x 370(H) mm

- Net weight: 5 kg (including can holder)

AT2E SSA-D secure seal analyzer is for testing the secure seal performance of products. With AT2E patent needle, it makes the installation and piercing very quick and easy in any medium. By vacuum technology and special design, the needle uses a function of self-holding on the tested products. However, the SSA-D can be compatible with using the needle of the classic Secure Seal Tester (typical screwed needle). It’s stainless steel design makes it resistant of any explosion during the test and ensures the safety of the operator.

SSA-D is equipped with a touching screen. It‘s visual and easy to operate. Adjustable pressure and holding time stage setting meets different test requests of various products.

Technical specifications:

- Measuring range: 0 to16.00bar

- Resolution: 0.01 bar

- Testson bottles,cans andpreforms

- AT2E patent special needle

- Touching screen display

- Units:bar /Psi

- Stainless steel secured device

- Setting of the level of pressure (regulator)

- 2 stages of pressure and holding time setting

- Resistant toexplosions

- Setting maximumpressure: 16 bar

- Compatiblewithtypical screwed needles

- 5-8 bar pressure source for vacuum function

- 0-16 bar pressure source for testing

- Overall size: 390 (L) x 550 (W) x 750 (H) mm

- Net weight: 30 kg

AT2E SSA-ECO secure seal analyzer is for testing the secure seal performance of products. With AT2E patent needle, it makes the installation and piercing very quick and easy in any medium. By vacuum technology and special design, the needle uses a function of self-holding on the tested products. However, the SSA-ECO can be compatible with using the needle of the classic Secure Seal Tester (typical screwed needle). It’s stainless steel design makes it resistant of any explosion during the test and ensures the safety of the operator.

Technical specifications:

- Measuring range: 0 to16.00bar

- Resolution: 0.5 bar

- Testson bottles,cans andpreforms

- AT2E patent special needle

- Analog display

- Units:bar /Psi

- Stainless steel secured device

- Setting of the level of pressure (regulator)

- Resistant toexplosions

- Setting maximumpressure: 16 bar

- Compatiblewithtypical screwed needles

- 5-8 bar pressure source for vacuum function

- 0-16 bar pressure source for testing

- Overall size: 390 (L) x 550 (W) x 690 (H) mm

- Net weight: 25 kg

AT2E SSA-AUTO Secure Seal Analyzer is for testing the secure seal performance on products. It’s an automated machine with automated piercing process and pressurizing process. Integrating AT2E patent needle, it allows automated installation. By vacuum technology and special design, the needle uses a function of self-holding on the tested products. Stainless steel design makes it resistant to any explosion during the test and ensures the operator’s safety.

SSA-AUTO is equipped with a touching screen. Visual and easy to operate. Adjustable pressure, pressurizing rate and holding time stage (up to 4 stages) setting meets different test requests and standard of various products.

Technical specifications:

- Measuring range: 0 to16.00bar

- Units:bar & psi

- Resolution: 0.01 bar

- Testson bottles,cans andpreforms

- AT2E patent special needle

- Sample range: 350 mm in height & 120 mm in diameter with 26-35 mm neck diameter (others on request)

- Touching screen display

- Stainless steel secured device: Resistant toexplosions

- Up to 4 stages of pressure, pressurizing rate and holding time setting

- Testing curve review

- 30 products memorization

- 10 operators memorization

- Configuration by protected password (administrator)

- Dynamic display: statistics/hour/date

- Display: product name/operator/batch N°/sample N°

- Maximumpressure protection setting

- 5-8 bar pressure source for vacuum function

- 0-16 bar pressure source for testing

- RS232 output (used to connect to software)

- Overall size: 610 (L) x 500 (W) x 1040 (H) mm

- Net weight: 60 kg

The SSA-PLC-12 Secure Seal Analyzer (12 Positions) is a special instrument developed by AT2E for control of the secure seal performance of caps on preforms.

Attributes:

- Muilt-position design, more convenient and efficient.

- PLC control ensures the high accuracy and reliability.

- Stainless steel frame, more safe and duable.

- Flexible position selection, each position can be controlled separately by system, users can choose to enable the positions (from 1 to 12) according to their needs.

- Linear pressurizing, able to set up to 4 pressurization steps, and hold the pressure according to the predefined period.

- Auto pressure compensation during test process

- Special designed clamping device, enhanced the sealing performance of test.

- Anti-explosion and clear observation window, safe and easy to observe the sample status during tests.

The TWB-1 Thermostatic Water Bath is a thermostatic water bath equipment that developed by AT2E. It is use to perform the thermostatic tests for products in various field, so that to provide reliable data for estimating the product quality.

Control by the electric cabinet

Technical specifications:

- Digital display shows real-time temperature, optional for stop heating or thermostatic timing after reached target temperature.

- Temperature range: Ambient temperature – 70°C

- Resolution: 0.1°C

- Air supply: 5 – 8 bar

- Heating tube: 1.5 KW * 2

- Dimension: 700 x 495 x 780 mm

- Weight: 50kg

- Power supply: 220V AC/ 50Hz

- Power: 3.2 KW

Tests on :

- Bottles: Glass or PET and Preforms

- Caps: Aluminium, other metal, plastic

- Cans: Aluminium, others

- Pots: caps, film, blisters etc.

- Vacuumadjustable up to- 999mb

- Box withdimensions upon request

- Box made of polishedtransparent PMMA(very rugged)

- Easy to use and safe

- Equipped with manometer

- Equipped with 3-directions valve for controlling the flow

- Accuracy: 0.5% of the measure

- Equipped with vacuum generator

- Runs with6 barnetwork

- Quick and easy of verification and calibration

- Adjustable temporization to keep vacuum or pressure

Tests on :

- Bottles: Glass or PET and Preforms

- Caps: Aluminium, other metal, plastic

- Cans: Aluminium, others

- Pots: caps, film, blisters etc.

- Vacuumadjustable up to- 999mbpressureup to 1 bar

- Box withdimensions upon request

- Box made of polishedtransparent PMMA(very rugged)

- Easy to use and safe by touch screen PLC Control Panel

- Dynamic display: Testing status / Date and time

- Display: Product name / Operator / Lot No. / Sample No.

- User defined test cycle (up to 16 modes). Pre-define up to 4 steps of each test. Vacuum level and holding time adjustable

- For each step. Satisfies different kinds of testing request Easy operation, only to select the pre-defined mode for starting a test no need to set the parameters every time

- 10 operators and 30 products memorisable

- Lot No. and Sample No. editable

- Review of the testing curve

- RS 232 C output

- Accuracy: 0.5% of the measure

- Delivered with high performance vacuum pump

- Runs with6 barnetwork

- Quick and easy verification and calibration

Tests on :

- Bottles: Glass or PET and Preforms

- Caps: Aluminium, other metal, plastic

- Cans: Aluminium, others

- Pots: caps, film, blisters etc.

- Vacuum adjustable up to – 999 mb

- Box with dimensions upon request

- Box made of polished transparent PMMA (very rugged)

- Easy to use and safe

- Touching screen display

- 2 stages of vacuum and holding time setting

- Accuracy: 0.5% of the measure

- Delivered with vacuum generator

- Runs with 6 bar network

- Verification and calibration quick and easy

The GBBT-1 is an instrument for testing the internal pressure resistance of glass containers. It has been widely used by the glass container manufacturers and users. As a standard testing instrument for the glass container industry, it offers an important technical reference to the manufacturers for maintaining or improving the product quality and performance.

Designed for easy operation and maintenance, comply with the testing standard of ISO 7458:2004.

The pressure test of containers is made up to a predefined pressure point (trial test) or until destruction.

Characteristics:

- PLC integrated & Touch screen control

- User defined test cycle (up to 4 steps of pressure and holding time) satisfies different test request

- Automatic clamping and filling system

- Easy operation

- Easy sample installing, with auto clamping and water filling system

- Linear pressurization

- Can store 10 operators and 30 products

- User defines the product lot number and sequence number

- Reviews the real-time testing curve

- Stainless steel design ensures the durability of tester

- Advanced safe door design ensures the safety of operator during a test.

- Special trash bin design makes the glass trash collection easily.

- RS232 output

- Can be connected to either printer or software

- Measuring range:0-57 bar (each station)

- Resolution: 0.1bar

- Sample range: by order

- Power:115 V/ 230 V, 50-60Hz

- Dimension: 620 (L) × 570 (W) × 820 (H) mm

- Net weight: 70 kg

- Compatible clamping system

- Professional Software for GBBT-1

The GBBT-2 is an instrument for testing the internal pressure resistance of glass containers. It has been widely used by the glass container manufacturers and users. As a standard testing instrument for the glass container industry, it offers an important technical reference to the manufacturers for maintaining or improving the product quality and performance.

Designed for easy operation and maintenance, comply with the testing standard of ISO 7458:2004.

The pressure test of containers is made up to a predefined pressure point (trial test) or until destruction.

Characteristics:

- Dual station which is more efficient and convenient for uninterrupted test

- PLC integrated & Touch screen control

- User defined test cycle (up to 4 steps of pressure and holding time) satisfies different test request

- Automatic clamping and filling system

- Easy operation

- Easy sample installing, with auto clamping and water filling system

- Linear pressurization

- Can store 10 operators and 30 products

- User define the product lot number and sequence number

- Reviews the real-time testing curve

- Stainless steel design ensures the durability of tester

- Advanced safe door design ensures the safety of operator during a test.

- Special trash bin design makes the glass trash collection easily.

- RS232 output

- Can be connected to either printer or software

- Measuring range:0-57 bar (each station)

- Resolution: 0.1bar

- Sample range: by order

- Power:115 V/ 230 V, 50-60Hz

- Dimension: 930 (L) x 540 (W) x 820 (H) mm

- Net weight: 95 kg

- Compatible clamping system

- Professional Software for GBBT-2

For PET bottles – Simulating filling process

PBBT-2 PET Bottle Burst Tester is specialized test equipment for testing the PET bottles. It’s designed in accordance with the three international test methods which are commonly used. Users can choose the test method basing on their requirement. The PBBT-2 is capable to test the capacity of resilience under certain pressure or the rupture test of the PET bottle.

Through the reproduction of the pressurization, the process has been linearized and it increases to the predetermined point or the point of bursting.

After selecting the test program, the cycle will start automatically depending on the settings. The touch screen displays the pressure value in real time and record the maximum pressure and burst pressure.

Optional part water recycling system could provide way of saving water and avoiding the unsteady pressure of tap water which may influence a normal test.

Additional booster could be chosen. It may help the PBBT-2 free of high pressure source.

Characteristics:

- Standard equipment for the PET bottle industry.

- 3internationaltest methods are available

- PLCintegrated & Touch screen control

- Automaticclamping and filling system

- Can store 10 operators and 30 products

- User defines the product lot number and sequence number

- Displaycurvesof pressure andvolume expansionduring the test

- Monitors and recordsthe temperature of thewaterduring the test

- Applicableto 2.5 L bottle(consult us forbigger size)

- Stainless steel design ensures the durability of tester

- RS232Cdata output: connected to either printer or software

- Integrated calibration function

- Measuring range: 0 – 20 bar

- Resolution:1 bar

- Samplerange: Up to 2.5 L bottle

- Expansionin volume: Up to 2 L

- Power supply:115/230V,50 – 60Hz

- Pressurerequired:3 barwater/ 20 bar air source

- Temperature range: 0 to 50 °C

- Rear Panel: RS232 serial output

- Dimensions: 740 (L) × 500 (W) × 920 (H) mm

- Net weight: 70 kg

Technical specifications:

Using by touch screen display

Measures in opening and closing directions

Measuring range: 00.00 to 99.00 Kgf.cm

3 measuring cycles (constant reading, Opening or Closing, Removal +Breaking)

Units: Kgf.cm / N.m / In

Read More

Technical specifications: CFR21-11 / FDA compatible

Free operator torque controller ( on-line )

Legal weighing control suitable in option

Secure seal test suitable ( automatic bubble point control )

Using by touch screen

Measures in openi

Read More

Technical specifications:

Using by touch screen display

Measures in opening and closing directions

Measuring range: 00.00 to 99.00 Kgf.cm

6 measuring cycles: Torque closing / Reach position / Release + break / Release + break + over screw

Read More

DESIGNED TO BE INSTALLED UNDER CAPPING HEADS

Our torque meters are designed with a special mechanical system for measuring torque which cancels most non- coaxial and top load influences on the measurement. These features cancel most operato

Read More

DESIGNED TO BE INSTALLED UNDER CAPPING HEAD – SCREW CAP -PILFER PROOF – SECURE CHILD

Our dynamometers include a special mechanical design permitting to avoid all influence from non-coaxial efforts. Also built-in a high speed electronic

Read More

DESIGNED TO BE INSTALLED UNDER CAPPING HEAD – SCREW CAP -PILFER PROOF – SECURE CHILD

AT2E’s BT ETA FORCE includes a special mechanical design permitting to avoid all influence from non-coaxial efforts. It’s also built in a high spee

Read More

Our Torque meters are designed with a special mechanical system for measuring torque which cancels most non- coaxial and top load influences on the measurement. These features cancel most operator influences on the measurement for maximum r

Read More

DESIGNED TO BE INSTALLED UNDER CAPPING HEADS

AT2E’s BT ETA TORQUE is built in with special mechanism permitting to avoid top load influence on measurement. It’s also built in a high speed electronic reading of measurements. Device can b

Read More

The BTLT-1 is an instrument for testing the resistance to Top load effort on glass containers. It has been widely used by the glass container manufacturers and users. As a standard testing instrument for the glass container industry, it off

Read More

This unit is used to get a rapid and accurate measure of angle α (see photo above) of the crown cap.

CET-1 Cork Extraction Tester is a force test system. It has been designed for wine producer and cork manufacturing industries. Easy to use, it allows to measure cork extraction or insertion and permits to improve the cork products and assem

Read More

CG-D Countersink Gauge is a digital gauge for measuring countersink depth of can and end. For fast and easy measurement, the zeroization base is equipped.

In order to avoid the manual recording error, the gauge can be connected to “SPC”

Read More

The CIDG-1 Can Internal Diameter Gauge is for quick checking the internal diameter of necked-in cans. For each diameter, a corresponding calibration block will be supplied along with the gauge.

It can be custom made to compatible for differ

Read More

CLA-ECO Can Leak Analyzer is specifically designed for analyzing the secure seal ability of the empty 3-pieces tinplate cans. Water bath design with free rotating can holders allows a 360° observation on the can body (especially welding po

Read More

A simple and convenient tool used to remove the center section of the can end while keeping the double seam intact.'

Caractéristiques techniques

Sample can diameter: 40-300 mm 3-piece cans

CO2-CS Automatic CO2 Calculating System is an innovative and full automatic CO2 content calculating system which is newly developed by AT2E. With the innovative shaking system and design, it will be safer for operator. Integrate touching

Read More

The CO2-P CO2 Purity Tester is a special instrument which is for calculating the purity of CO2. The principle is based on absorption burette to measure the impurities (O2 and N2 e.g.) of CO2 in a mixture of gases.

The CO2-P CO2 Purity

Read More

AT2E CO2DA – Automatic Shaker & CO2 Calculator is a special instrument which is for calculating the carbon dioxide content in the filled drink in glass/PET bottles and cans. The simple operation which also guarantees high reproducibil

Read More

For a constant quality and taste of all kinds of carbonated drinks, the critical parameter is the CO2 (carbon dioxide) content in the liquid.

Our CO2 measuring device is a standard equipment and widely used in breweries and in the non-alc

Read More

Presentation:

This aphrometer is designed to check the pressure after the disgorging process of sparkling wines.

It measures the pressure in the champagne bottles topped on with a wire-hood and a cork.

Its strong mechanism allows it to pier

Read More

Presentation:

This aphrometer is designed to check the pressure during the secondary fermentation.

This Champagne pressure gauge checks instantaneously the pressure in the bottles topped on with a crown cap with or without plastic shutter.

Read More

CSM Can Seam Micrometers is used for a quick measurement of seam thickness and seam length. It’s an easy-operated tool and widely use in canning industry.

Technical specifications:

Measuring range: 0-13 mm

Resolution: 0.001 mm

Accuracy:

Read More

Resistance to tensile or compression

DYNAMOMETER WITH AT2E MECHANIC

Range: 20, 100, 200, 500N

Please specify when ordering

Measure tension and compression.

Reading on the dial needle

Zero Recalibration by a touch

Accuracy

Read More

ECDG-1 End Curl Diameter Gauge is for quick measure of the Curl Diameter of ends.

Easy-operation design offers a fast and accurate measurement of the Curl Diameter. For each end type, a corresponding calibration block will be supplied along

Read More

Simple and useful measuring tool for fill height measurement. It’s designed for all size bottles. Gauge may be preset in inches or millimeters to check fill height level on production line or may be used to measure exact fill point of bot

Read More

FHS Fill height syringe is used to adjust water level in a bottle to a pre-determined fill height.

It’s a useful tool for accurate and quick checking the content of bottle.

The “FT-1 Fatigue Tester” is used to test and analyze the durability and quality of all packaging in compression or traction direction. It’s widely used in cosmetic, pharmaceutical and other industries.

It’s an automated tester and

Read More

FWG-1 Flange Width Gauge is used to measure the flange width of empty cans.

Easy-operation design offers a fast and accurate measurement of flange width.

In order to avoid the manual recording error, the gauge can be connected to SPC system

Read More

Special instrument for testing the impact resistance ability of various glass bottles and jars.

Attribute

The sample clamp is able to move flexibly on vertical or horizontal direction, convenient for adjusting the sample position.

Instrume

Read More

GDTB-4 Gauge Data Transportation Box is a data process box specially developed for collecting the data from Mitutoyo digital gauges. With the GDTB, users are able to collect the Mitutoyo digital gauges’ data and send to data acquisition s

Read More

This unit has an excellent basis for measuring. It’s easy to use. Crown cap height and thickness are measured by analog indicator. It is widely used in crown cap, brewery and beverage industries.

Technical specifications:

Measuring range

Read More

The HWBC-1 Hot Wire Bottle Cutter offers an easy and cost saving way for cutting containers for section weight analysis. A clean section without deformation will be obtained by a quick cutting of bottles through heated hot wires. A precisio

Read More

AT2E innovative HWBC-2 Hot Wire Bottle Cutter offers an automated and cost saving way for cutting containers for section weight analysis. A clean section without deformation will be obtained by a quick cutting of bottles through heated hot

Read More

The aim of this unit is to test whether the internal diameter of the tested sample is within standard or not.

Judgment of reference: the small end must adapt to the internal circle of the samples, while the larger end should not adapt to t

Read More

The aim of this unit is to test whether the outside diameter of the tested sample is within standard or not.

Judgment of reference: the samples must adapt to the larger hole, while the samples must not adapt to the small hole.

It can be cu

Read More

Allows to cut easily the bottles neck in order to prepare the bubble test with adapted cap holder or to measure some accurate points on a preform.

Easy operation.

Cutting range ( diameter ) :0 to 42 mm / other on request

Presentation:

This aphrometer checks the evolution of the pressure during the secondary fermentation.

Remove one bottle without cap from the filling machine and put the aphrometer on the bottleneck.

The permanent aphrometer will remain on t

Read More

Quality control gauges for checking the threaded tops of glass and plastic containers. Check the threads, outside diameter, spacing, etc.

Comb. Finish Gauge 28mm-PCO-1816 PET

Comb. Finish Gauge 28mm Pet/28-969-1716

Comb. Finish Gauge 38mm G

Read More

Strength pull off cap tester

Features:

Easy to use

High repeatability in testing

Built-in dynamometer with software

Dynamometers specifications:

Range: 50 / 200 / 1000 N (Please specify when ordering)

Measure tensile &

Read More

The “PPG-A” and “PPG-D” are used to measure the perpendicularity (deviation) of the preform and it’s a standard equipment for PET and beverage industries.

With special designed changing & clamping part, it can ensure the accur

Read More

Many typical laboratory functions have been expanded to include a clear graphics screen, which shows the relevant information visually and makes it significantly easier to operate and read the weights off the display

Navigation pad for sup

Read More

PTG -1 Plate Thickness Gauge is for quick checking of the thickness of plates.

Easy-operation design offers a fast and accurate measurement of the plate thickness.

In order to avoid the manual recording error, the gauge can be connected to

Read More

The “PVG” is used to measure pressure or vacuum of can or bottle.

Simply place the sample under the entity manometer or vacuum meter and lower the lever. Then read the value.

Advantages:

Easy to use

Available with analog or digital ind

Read More

“PVG-P” is the portable model for measuring pressure or vacuum into bottle.

Install the PVG-P under the finish neck and adjust the needle on the cap’s center, then screw the nut.

The needle will pierce the cap without leakage and chec

Read More

The AT2E SCT-D Stress Crack Tester is designed to test the internal stress in bottle base and for determining the stress crack resistance of blow-molded PET carbonated soft drink bottles by measuring the propensity for base cracking upon ex

Read More

The AT2E Stress Crack Tester is designed to test the internal stress in bottle base and for determining the stress crack resistance of blow-molded PET carbonated soft drink bottles by measuring the propensity for base cracking upon exposure

Read More

Presentation:

The simplified Aphrometer is designed to check the pressure and the vacuum in the bottles of still wine (Bordeaux bottles, Burgundy bottles).

Thanks to its sting this pressure gauge pierces corks and some synthetic corks, but

Read More

SLG-1 Seam Length Gauge is for quick measure of the Seam length (Seam height)

Easy-operation design offers a fast and accurate measurement of the Seam length (Seam height).

Reliable design, invariable measuring pressure and measuring angle

Read More

STG-1 Seam thickness gauge is used to measure the Seam thickness of cans.

Easy-operation design offers a fast and accurate measurement of seam thickness.

With measure angle compensation and adjusted center measure point, the can could be au

Read More

AT2E TCT-2 measure the resistance to tear or top load force (traction or compression) for all kind of packaging. Sample installed on the support and the force is raised in tear or top load direction gradually. The distance between the gauge

Read More

Our torque tester are designed with a special mechanical system for measuring torque which cancels most non-coaxial and top load influences on the measurement. These features cancel most operator induced influences on the measurement for ma

Read More

Technical specifications:

7″ Touch screen color display

Measures opening and closing directions

0.030 to 4.000 Kgf.cm in high accuracy mode

Measuring range: 00.00 to 99.00 Kgf.cm

3 measuring modes (mean, peak, peak+infos)

Special mode RE

Read More

Our torque meters are designed with a special mechanical system for measuring torque which cancels most non- coaxial and top load influences on the measurement. These features cancel most operator influences on the measurement for maximum r

Read More

AT2E ER-1 Enamel Rater offers a fast and accurate method to measure the integrality of internal coating of containers. A measuring will be started automatically when the electrical probe is inserted and contacts the solution inside the cont

Read More

AT2E SSA-D secure seal analyzer is for testing the secure seal performance of products. With AT2E patent needle, it makes the installation and piercing very quick and easy in any medium. By vacuum technology and special design, the needle u

Read More

AT2E SSA-ECO secure seal analyzer is for testing the secure seal performance of products. With AT2E patent needle, it makes the installation and piercing very quick and easy in any medium. By vacuum technology and special design, the needle

Read More

AT2E SSA-AUTO Secure Seal Analyzer is for testing the secure seal performance on products. It’s an automated machine with automated piercing process and pressurizing process. Integrating AT2E patent needle, it allows automated installatio

Read More

The SSA-PLC-12 Secure Seal Analyzer (12 Positions) is a special instrument developed by AT2E for control of the secure seal performance of caps on preforms.

Attributes:

Muilt-position design, more convenient and efficient.

PLC control ensu

Read More

The TWB-1 Thermostatic Water Bath is a thermostatic water bath equipment that developed by AT2E. It is use to perform the thermostatic tests for products in various field, so that to provide reliable data for estimating the product quality.

Read More

Tests on :

Bottles: Glass or PET and Preforms

Caps: Aluminium, other metal, plastic

Cans: Aluminium, others

Pots: caps, film, blisters etc.

LEAK DETECTION BY SETTING VACUUM WITH OR WITHOUT STEP

Specifications:

Vacuumadjustable up t

Read More

Tests on :

Bottles: Glass or PET and Preforms

Caps: Aluminium, other metal, plastic

Cans: Aluminium, others

Pots: caps, film, blisters etc.

Specifications:

Vacuumadjustable up to- 999mbpressureup to 1 bar

Box withdimensions upon r

Read More

Tests on :

Bottles: Glass or PET and Preforms

Caps: Aluminium, other metal, plastic

Cans: Aluminium, others

Pots: caps, film, blisters etc.

LEAK DETECTION BY SETTING VACUUM WITH OR WITHOUT STEP

Specifications:

Vacuum

Read More

The GBBT-1 is an instrument for testing the internal pressure resistance of glass containers. It has been widely used by the glass container manufacturers and users. As a standard testing instrument for the glass container industry, it offe

Read More