- Enamel finished steel-aluminium case, benchtop version.

- Insulated metal jacket conform to ASTM, IP, DIN and ISO standard methods.

- One glass sample container conform to ASTM, IP, DIN and ISO standard methods.

- Two models, one for jacket temperatures till -60°C (suitable for tests at standard temperature of 48, 24, 0, -18, -33 and -51°C) and one till -80°C (suitable also for -69°C tests) with +/- 0.2°C regulation accuracy. Both units are equipped with a patent-pending integrated cooling system based on thermoelectric cooling: in this way we have reduced dimensions, weight, power consumption, noise and heat dissipation making moreover the equipment more reliable since single-stage cooling compressors require much less maintenance if compared with cascade double-stage ones.

- Micro Thermal detection of pour point. Motorized arm that lifts and tilts the sample container out of the jacket at programmable intervals: mimic ASTM D 97.

- Temperature sensor: Pt100 RTD. Accuracy of temperature reading: +/- 0.1°C.

- 8.4” touch screen interface that permits to introduce the analytical data, control the test and display the results. Tests can be run acc. to ASTM/ISO methods or to user defined methods. Software includes diagnose and calibration tools with all modern QC routines.

- Two USB, one RS-232 and one Ethernet connector for connecting to printers and network even through wireless dongles.

- English written user manual. CE marked.

- For 220 V/50 Hz connections: 700 W power consumption (PP-60) and 1000 W (PP-80).

- Dimensions and weights (l x w x h) pour point : 350x700x700 mm, 40 kg (PP-60) and 400x750x750 mm, 50 kg (PP-80).

- Enamel finished steel-aluminium case, benchtop version.

- Insulated metal jacket conform to ASTM, IP, DIN and ISO standard methods.

- One glass sample container with mirror conform to ASTM, IP, DIN and ISO standard methods.

- Two models, one for jacket temperatures till -60°C (suitable for tests at standard temperature of 48, 24, 0, -18, -33 and -51°C) and one till -80°C (suitable also for -69°C tests) with +/- 0.2°C regulation accuracy. Both units are equipped with a patent-pending integrated cooling system based on thermoelectric cooling: in this way we have reduced dimensions, weight, power consumption, noise and heat dissipation making moreover the equipment more reliable since single-stage cooling compressors require much less maintenance if compared with cascade double-stage ones.

- Optical detection of cloud point through IR sensor.

- Temperature sensor: Pt100 RTD. Accuracy of temperature reading: +/- 0.1°C.

- 8.4 inches touch screen interface that permits to introduce the analytical data, control the test and display the results. Tests can be run acc. to ASTM/IP/ISO/DIN methods or to user defined methods. Software includes diagnose and calibration tools with all modern QC routines.

- Two USB, one RS-232 and one Ethernet connector for connecting to printers and network even through wireless pendrives.

- English written user manual. CE marked.

- For 220 V/50 Hz connections: 700 W power supply (CP-60) and 1000 W (CP-80). Dimensions and weights (l x w x h): 350x700x700 mm, 40 kg (CP-60) and 400x750x750 mm, 50 kg (CP-80).

The apparatus consists of a benchtop case containing the cooling compressor with the cooling jacket and supporting the head and the control box. Stirring of the sample is provided by an electric motor adjusted for 75 strokes/min and connected to a coil. Temperature is acquired by means of a Pt100 RTD. The apparatus needs a PC to operate. A software running under Windows Xp/Vista/7 permits to perform the analysis fully automatically, store data and print reports.

- Enamel finished steel case, benchtop version.

- Double stage cooling compressor (for jacket temperatures down to –85°C).

- Electrically powered sample support: it permits to lift the sample out of the jacket and to insert it at the beginning of the test.

- Electric sample stirrer with coil. Stirrer speed: 75 strokes/min.

- Pt100 RTD for sample temperature recording: complete with cable and connector.

- Software running under Windows Xp/Vista/7 that permits to introduce the analytical data, controls the test, displays the results and allows printouts. Software includes calibration tools with all modern QC control and record.

- English written user manual.

- CE marked.

- For 220 V/50 Hz connections: 1600 W power consumption.

- Dimensions (l x w x h): 700 x 600 x 900 mm. Weight: 120 kg. approx.

- PC not included.

AD1177-110 Apparatus for the determination of Freezing Point of antifreeze liquids for PC connection

ACCESSORIES

PC01 Desktop PC

PRN01 Printer

CAL001 PT100 simulator

CAL002 Officially certified PT100 simulator

CONSUMABLES

AD1177-C00 Glass sample container, 200 ml

Specifications may vary without notice.

The apparatus is supplied bare without glassware (if any), accessories and consumables.

- Enamel finished steel-aluminiumcase, benchtop version.

- Insulated metal jacket conform to ASTM, IP, DIN and ISO standard methods. - One glass sample container conform to ASTM, IP, DIN and ISO standard methods.

- Two models, one for jacket temperatures till -60°C (suitable for tests at standard temperature of -34 and -51°C) and one till -80°C (suitable also for -67°C tests) with +/- 0.2°C regulation accuracy. Both units are equipped with a patent-pending integrated cooling system based on thermoelectric cooling: in this way we have reduced dimensions, weight, power consumption, noise and heat dissipation making moreover the equipment more reliable since single-stage cooling compressors require much less maintenance if compared with cascade double-stage ones.

- Automatic determination of CFPP : sample temperature decrease is monitored by the software and vacuum applied every 1°C. Two IR photocells permit to measure CFPP during aspiration or release.

- Temperature sensor: Pt100 RTD. Accuracy of temperature reading: +/- 0.1°C. - Filtration unit composed by 20 ml pipette, filter holder and 45 microns filter. - 3-way solenoid valve for vacuum controlled by the software. Vacuum unit required if not already available.

- 8.4” touch screen interface that permits to introduce the analytical data, control the test and display the results. Tests can be run acc. to ASTM/IP/EN methods or to user defined methods. Software includes diagnose and calibration tools with all modern QC routines.

- Two USB, one RS-232 and one Ethernet connector for connecting to printers and network even through wireless dongles. - English written user manual. CE marked. - For 220 V/50 Hz connections: 500 W power consumption.

- Dimensions and weights (l x w x h): 350x700x700 mm, 40 kg (CFPP-60) and 400x750x750 mm, 50 kg (CFPP-80).

- Enamel finished steel-aluminium case, benchtop version.

- Insulated metal jacket conform to ASTM, IP, DIN and ISO standard methods.

- One glass sample container with mirror conform to ASTM, IP, DIN and ISO standard methods.

- Two models, one for jacket temperatures till -60°C (suitable for tests at standard temperature of 48, 24, 0, -18, -33 and -51°C) and one till -80°C (suitable also for -69°C tests) with +/- 0.2°C regulation accuracy. Both units are equipped with a patent-pending integrated cooling system based on thermoelectric cooling: in this way we have reduced dimensions, weight, power consumption, noise and heat dissipation making moreover the equipment more reliable since single-stage cooling compressors require much less maintenance if compared with cascade double-stage ones.

- Optical detection of cloud point based on continuous reflected IR light percentage . Accuracy of temperature reading: +/- 0.1°C.

- Micro Thermal detection of pour point. Motorized arm that lifts and tilts the sample container out of the jacket at programmable intervals: mimic ASTM D 97. Accuracy of temperature reading: +/- 0.1°C.

- 8.4” touch screen interface that permits to introduce the analytical data, control the test and display the results. Tests can be run acc. to ASTM/ISO methods or to user defined methods. Software includes diagnose and calibration tools with all modern QC routines.

- Two USB, one RS-232 and one Ethernet connector for connecting to printers and network even through wireless dongles.

- English written user manual. CE marked.

- For 220 V/50 Hz connections: 700 W power consumption (CPPP-60) and 1000 W (CPPP-80).

- Dimensions and weights (l x w x h): 350x700x700 mm, 40 kg (CPPP-60) and 400x750x750 mm, 50 kg (CPPP-80).

- Enamel finished steel-aluminium case, benchtop version.

- One glass sample container conform to ASTM, IP, DIN and ISO standard methods.

- Thermally insulated jacket capable to reach -80°C in less than 30 min equipped with a patent-pending integrated cooling system based on thermoelectric cooling: this technology has permitted to reduce dimensions, weight, power consumption, noise and heat dissipation making the equipment more reliable since single-stage cooling compressors require much less maintenance if compared to cascade double-stage ones.

- Optical detection of freezing point through IR sensor: sample is cooled until crystals appear and then heated until their disappearance to determine the result.

- Temperature sensor: Pt100 RTD. Accuracy of temperature reading: +/- 0.1°C.

- Electric stirrer 75 rpm complete with brass stirring coil and mechanism.

- 8.4 inches touch screen interface that permits to introduce the analytical data, control the test and display the results. Tests can be run acc. to ASTM/IP/ISO/DIN methods or to user defined methods. Software includes diagnose and calibration tools with all modern QC routines.

- Two USB, one RS-232 and one Ethernet connector for connecting to printers and network even through wireless pendrives.

- English written user manual. CE marked.

- For 220 V/50 Hz connections: 1000 W power supply.

- Dimensions and weights (l x w x h): 400 x 750 x 750 mm, 50 kg.

|

The apparatus consists of a benchtop case which houses the electro-mechanical components and a miniature PC with touch screen. A software running under Windows permits to select the test method and the test parameters, run the test automatically, store, retrieve and print data, diagnose and calibrate the instrument offering in the meanwhile all the features of Windows systems such as LAN connectivity. The instrument is equipped with a sensor for barometric pressure for the correction of the results towards atmospheric pressure.

|

- Enamel finished benchtop steel and aluminium case.

- Cast iron air stove identical to the one reported on the ASTM method.

- Brass oil cup and lid with insulating handle. Jacket for glass-coated Pt100 RTD in the cover (n°1 Pt100 with cable and quick connector supplied with the instrument).

- Brass oil cup and lid with insulating handle. Jacket for glass-coated Pt100 RTD in the cover (n°1 Pt100 with cable and quick connector supplied with the instrument).

- Electric stirrer that stops during flame dipping. Stirrer speed: 105 rpm for ASTM D 93 method A and C and 250 rpm for method B. Other speeds can be selected for custom methods.

- Automatic flame dipping: provision for gas or electric ignitor.

- Electric heating.Measuring range: from ambient to 400°C.

- Electric cooling fan to cool down the stove at the end of the test.

- Ignition system: a slide supporting both ignitor and pilot flame permits a quicker and safe removal of the cover at the end of the test, avoiding to disconnect electric ignitor cables and/or gas ignitor tubes that remain always connected. It is possible to use both gas or electric ignitor: when a gas ignitor is used, the electric one can be used as pilot flame

- PC based controller with 6” color touch-screen interface. IP 65 front protection.

- Software characteristics: selection of the ASTM/IP test method or setup of up to 40 custom methods, introduction of the testparameters through the touch screen, possibility to change the setpoint during the test, selectable rapid preheating (in case of sample with high flash point is possible to pre-heat the sample at a higher rate to speed-up the test), “search” option (forsample with unknown flash point), selectable cooling time, storage of-up to 800 test results and possibility to retrieve and print test reports, calibration and diagnostic routines.

- LAN connectivity: the apparatus can be connected directly to a hub to become part of the user network: a software supplied with the apparatus permits to retrieve data also from another PC.

- Two USB and one RS-232 serial interfaces.

- Flash point detection through ionization sensor: the apparatus also provides an alert if a flash has occurred at the first flame application, warning that the test result is not reliable. The flash point temperature remains shown on the display until the operator’s acknowledgement: buzzer to alert the user.

- Safety device is provided to stop the analyzer if a flash has not been detected at a temperature 30°C over the preset value. This safety device could be excluded to perform "search" tests.

- English written user manual. Microsoft Windows Xp original license.

- Dimensions (l x w x h): mm 280 x 480 x 650. Weight: kg 20 approx.

- For 220 V/50 Hz connections: 800 W power consumption.

- CE marked.

The apparatus is a benchtop model which houses the mechanical components and a miniature PC with touch screen. A software running under Windows Xp permits to select the test method and the test parameters, run the test automatically, store, retrieve and print data, diagnose and calibrate the instrument offering in the meanwhile all the features of Windows systems such as LAN connectivity. The instrument is equipped with a sensor for the correction of the results towards atmospheric pressure.

- Enamel finished steel case, benchtop version.

- Electric heating plate.

- Brass oil cup with insulating handle (n°1 Pt100 with cable and quick connector supplied with the instrument).

- Electronically driven mechanism that passes the flame over the cup at the correct intervals for the correct amount of time: electric pilot flames in conjunction with a solenoid valve on the gas line automatically light the flame and relight in case it extinguishes during the test.

- Second generation ionization flash sensor.

- Flame extinguisher: automatically extinguishes the flame covering the cup in case a fire is detected or after fire point detection.

- PC based controller with touch-screen interface.

- Software characteristics: selection of the ASTM/IP test method or setup of up to 40 custom methods, introduction of the test parameters through the touch screen, possibility to change the setpoint during the test, “search” option (for sample with unknown flash point), selectable cooling time, storage of up to 400 test results and possibility to retrieve and print test reports, LAN connectivity, calibration and diagnostic routines.

- LAN connectivity: the apparatus can be connected directly to a hub to become part of the user network: a software supplied with the apparatus permits to retrieve data also from another PC.

- Flash and fire point detection through ionization sensor: the apparatus also provides an alert if a flash has occurred at the first flame application, warning that the test result is not reliable. The flash point temperature remains shown on the display until the operator’s acknowledgement.

- Safety device is provided to stop the analyzer if a flash has not been detected at a temperature 30°C over the preset value or at a temperature of 400°C. This safety device could be excluded to perform "search" tests.

- English written user manual. Microsoft Windows original license.

- Dimensions (l x w x h): mm 360 x 460 x 680. Weight: kg 36 approx.

- For 220 V/50 Hz connections: 600 W power consumption.

- CE marked.

AD0092-600 Apparatus

ACCESSORIES

AD0092-A00 Printer

CAL001 PT100 simulator

CAL002 Officially certified PT100 simulator

CONSUMABLES

AD0092-C00 Oil cup

AD0092-C02 Pt100 probe

AD0092-C03 Electric ignitor

Specifications may vary without notice.

The apparatus is supplied bare without glassware (if any), accessories and consumables.- Enamel finished steel case.

- Double wall brass heating bath with hole for water filling.

- Electric heater with voltage regulator.

- Pt100 probe for sample temperature acquisition.

- Digital display for sample temperature, 0.1°C accuracy.

- One brass cup with handle.

- One lid with flame exposure device, thermometer well, gas ignitor and pilot flame.

- 30 rpm electric stirrer with separate switch.

- English written user manual.

- For 220 V/50 Hz connection: 500 W power consumption.

- Dimensions (l x w x h): 360 x 360 x 400 mm. Weight: 12 kg approximately.

- CE approved.

The apparatus is a benchtop model which houses the air bath stove and the stirrer motor: differently from other apparatus on the market, our instrument is equipped with a fan that cools down the stove quickly after the test.

- Enamel finished benchtop steel case.

- Cast iron stove, electrically heated with stainless steel external shield.

- Voltage regulator with dial on the front panel.

- Pt100 probe for sample temperature acquisition.

- Digital display for sample temperature, 0.1°C accuracy.

- Oil cup, brass, complete with filling mark. Insulating handle.

- Lid with flame dipping mechanism.

- Electric stirrer, 100 or 250 rpm.

- Electric fan for a quick cooling of the stove at the end of the test.

- English written user manual.

- For 220V/50 Hz connections, 900 W power consumption.

- Dimensions (l x w x h): mm 240 x 330 x 450. Weight: 10 kg approximately.

- CE approved.

AD0093-120 Apparatus (for ASTM D 93 method A, B and C)

ACCESSORIES

CAL001 PT100 simulator

CAL002 Officially certified PT100 simulator

CONSUMABLES

AD0093-C00 Oil cup

AD0093-C01 Lid

AD0093-C02 PT100 probe

AD0093-C04 Gas ignitor

TA009C-N00 ASTM 9C thermometer (-5/+110°C)

TA010C-N00 ASTM 10C thermometer (+90/+370°C)

Specifications may vary without notice.

The apparatus is supplied bare without glassware (if any), accessories and consumables.

The apparatus consists of a benchtop steel case supporting the electrical heater, the gas ignitor and the thermometer support.

- Enamel finished benchtop steel case.

- Electric heating plate with stainless steel support.

- Electronic temperature regulator with dial on the front panel.

- Oil cup, brass with insulating handle.

- Gas ignitor, stainless steel, complete with valve and with support that permits to pass the flame over the cup at the correct distance.

- Pt100 probe for temperature acquisition.

- Support for Pt100 probe.

- Digital display for sample temperature, 0.1°C accuracy.

- English written user manual.

- For 220 V/50 Hz connections, 500 W power consumption.

- Dimensions (l x w x h): mm 360 x 360 x 300. Weight: 8 kg approximately.

- CE approved.

AD0092-110 Apparatus with digital display, 0.1°C accuracy (complete with PT100 RTD with cable and connector)

ACCESSORIES

CAL001 PT100 simulator

CAL002 Officially certified PT100 simulator

CONSUMABLES

AD0092-C00 Oil cup

AD0092-C01 PT100 probe

TA011C-N00 ASTM 11C thermometer (-6°C/+400°C)

Specifications may vary without notice.

The apparatus is supplied bare without glassware (if any), accessories and consumables.

- Powder coated steel frame supporting two Pyrex jars, one for tests at 24 and one for tests at 93.5°C.

- Aluminium covers, each with two holes for the graduate test cylinders: locking clamps to hold the cylinders in position and thermometer jacket for ASTM 12C thermometer on each cover.

- Electrical bath stirrer on the jar cover.

- Stainless steel heaters.

- Two stainless steel cooling coils in the 24°C jar: one permits to maintain 24°C in the jar by circulating tap water and one permits to cool down the air used in sequence II.

- Two or four electronic mass flow controllers with 0-200 ml/min scale and 0.1% F.S. precision.

- Electronic controller that permits to run the test completely automatically: selectable waiting, blowing and alarm time. The controller provides also to maintain the jars at the prescribed temperatures with 0.1°C accuracy. 8.4” touch screen display. Calibration, diagnostic and data storage routines. Temperature measuring elements: PT100 RTD.

- Operating range: from ambient to 100°C.

- One Ethernet, two USB and one serial port.

- Safety transparent shield surrounding 93.5°C bath.

- Safety devices against overheating and low level on both jars.

- Easy access control box: it can be removed in case of malfunctionment for easy transportation.

- English written user's guide and installation instructions.

- For 220V / 50Hz connections. Power consumption 2500 W.

- Dimensions (l x w x h): mm 1050 x 460 x 720. Weight: kg 55 approx.

- CE marked.

The apparatus consists of a steel frame supporting the control box, the jar and an electric lift that permits to move the sample stirrer up and down in the test funnel. The stirrer assembly can also be removed from the unit for cleaning. Stirrer speed is continuously showed on a digital tachometer.

- Borosilicate glass jar 500 mm depth, mounted on a enamel finished benchtop steel frame.

- Anodized aluminium cover with four-position turntable for the insertion of four graduated separatory funnels: a positioning device permits to locate the funnels exactly below the stirrer and avoid glassware breaking due to positioning mistakes.

- Stainless steel heaters and electrical bath stirrer.

- Variable speed electrical sample stirrer mounted on a electrical device which permits to lift and lower the stirrer easily in the sample. The stirrer assembly is also removable for cleaning.

- Digital tachometer in the control box which continuously shows the stirrer speed.

- Electromechanical timer which automatically stops the sample stirrer after 5 minutes of stirring.

- Microprocessor thermoregulator with built-in digital thermometer 0.1°C accuracy. Probe: PT100 RTD. Regulation accuracy ± 0.1°C. Working range: from ambient to 90°C.

- Safety devices against overheating and low-level.

- Easy access control box placed on the right side of the apparatus containing all the electronic and electrical components: aluminium control panel with english written indications.

- English written user manual.

- For 220 V/50 Hz connections. Power consumption 1800 W.

- Dimensions (l x w x h): mm 500 x 460 x 1100 approx. Weight: kg 50 approx.

- CE marked.

AD2711-100 Apparatus

ACCESSORIES

AD2711-A00 Table support for four funnels

CAL001 PT100 simulator

CAL002 Officially certified PT100 simulator

CONSUMABLES

AD2711-C00 500 ml graduated funnel, Pyrex glass

The apparatus consists of a benchtop frame supporting the 1000 mm U-tube manometer, a regulating valve, 1 m of 8 mm inside diameter brass tubing, a 250 ml cylinder and a 500 ml filtering flask with rubber stopper and outlet tube. The apparatus can be used to check both cylindrical (Mott) and spherical (Norton) diffusers for maximum pore diameter and permeability.

- Enamel finished benchtop frame.

- Maximum pore diameter determination assembly consisting in a electrically powered piston that permits to raise the pressure at the prescribed rate of 50 Pa/min inside the diffuser when immersed in water or propan-2-ol. This device has been adopted since it is practically impossible to control the correct increase of pressure with a valve (50 mm of water column/min is a very small increase).

- One precision regulating valve for the permeability test. It permits to regulate the air pressure at 250 Pa in the diffuser circuit when the diffuser is connected to the wet test meter.

- One 1000 ml U-tube manometer mounted on a wooden support with adjustable mm scale.

- One 250 ml graduate cylinder.

- One 500 ml filtering flask with rubber stopper and air outlet tube . Hose connector for connection to the wet test meter.

- English written user manual.

- CE marked.

- For 220V / 50Hz connection. Power consumption: 100 W approx.

- Dimensions (l x w x h): 500 x 300 x 1200 mm approx. Weight: 10 kg approx.

- Wet test meter not included.

AD0892-300 Apparatus

ACCESSORIES

AD0892-A00 Wet test meter

AD0892-A01 Official certified wet test meter

- Steel frame supporting one Pyrex jar, suitable for tests at 24 and at 93.5°C.

- Aluminium cover with two holes for the cylinders: locking clamps to hold the cylinders in position and thermometer jacket.

- Electrical bath stirrer on the jar cover.

- Stainless steel heaters.

- Stainless steel cooling coils: when connected to a cold water source, it permits to keep the bath temperature (24°C) prescribed in ASTM D 892 sequence 1.

- High precision variable area flowmeters complete with needle valve, supports and diffuser connections. Individual calibration certificates.

- Microprocessor thermoregulator with PID action and built-in digital display 0.1°C accuracy. Probe: Pt100 RTD.

- Safety devices against overheating and low level.

- Easy access control box.

- English written user's guide and installation instructions.

- For 220 V/50 Hz connections. Power consumption 2200 W.

- Dimensions (l x w x h): mm 450 x 420 x 680. Weight: kg 30 approx.

- CE marked.

- Version with mass flow controller and software also available.

AD0892-100 Single-unit apparatus

ACCESSORIES

AD0892-A00 Wet test meter

AD0892-A01 Officially certified wet test meter

AD0892-A02 Air pump

AD0892-A03 Glass drying tower

CAL001 PT100 simulator

CAL002 Officially certified PT100 simulatorCONSUMABLES

AD0892-C00 Graduate pyrex glass cylinder

AD0892-C01 Rubber stopper with air inlet and outlet

AD0892-C02 Norton spherical Alundum gas diffuser stone (certified for permeability and pore size)

AD0892-C03 Mott stainless steel cylindrical gas diffuser (certified for permeability and pore size)

TA012C-N00 ASTM 12C thermometer (-20°C/+102°C)

Specifications may vary without notice.

The apparatus is supplied bare without glassware, diffusers, accessories and consumables.

The apparatus consists of a steel case containing a Pyrex jar with an insulated cover that allows to insert two cylinders without necessity of any steel ring to avoid floatation, two high precision flowmeters and a control box containing all the electronics.

- Enamel finished steel case containing one Pyrex jar, suitable for tests up to 160°C. Double-walled window on the front.

- Insulated cover with two holes for the cylinders: locking clamps to hold the cylinders in position and thermometer jacket.

- Electric stirrer.

- Stainless steel heaters.

- Two high-precision variable area flowmeters complete with needle valve, supports and diffuser connections. Individual calibration certificates.

- Microprocessor thermoregulator with PID action and built-in digital display 0.1°C accuracy. Probe: Pt100 RTD.

- Safety devices against overheating and low level.

- Easy access control box.

- English written user's guide and installation instructions.

- For 230V/50 Hz connections. Power consumption 2200 W.

- Dimensions (l x w x h): mm 680 x 540 x 800. Weight: kg 35 approx.

- CE marked.

- Version with mass flow controller and software also available.

AD6082-100 Apparatus

ACCESSORIES

AD6082-A00 Wet test meter

AD6082-A01 Air pump

AD6082-A02 Glass drying tower

CAL001 PT100 simulator

CAL002 Officially certified PT100 simulator

CONSUMABLES

AD6082-C00 Graduate Pyrex glass cylinder

AD6082-C01 Rubber stopper with air inlet and outlet tubes

AD6082-C02 Mott stainless steel cylindrical gas diffuser

TA041C-N00 ASTM 41C thermometer (+98°C/+152°C)

Specifications may vary without notice.

- Steel frame supporting two Pyrex jars, one for tests at 24 and one for tests at 93.5°C.

- Aluminium covers with two holes for the cylinders: locking clamps to hold the cylinders in position and thermometer jacket.

- Electrical bath stirrer on the jar cover.

- Stainless steel heaters.

- Stainless steel cooling coils: when connected to a cold water source, it permits to keep the bath temperature (24°C) prescribed in ASTM D 892 sequence 1.

- High precision variable area flowmeters complete with needle valves, supports and diffuser connections. Individual calibration certificates.

- Microprocessor thermoregulator with PID action and built-in digital display 0.1°C accuracy (one for each bath). Probe: Pt100 RTD.

- Safety devices against overheating and low level on both jars.

- Easy access control box.

- English written user's guide and installation instructions.

- For 220V / 50Hz connections. Power consumption 2200 W.

- Dimensions (l x w x h): mm 1050 x 420 x 680. Weight: kg 60 approx.

- CE marked.

- Version with mass flow controller and software also available.

AD0892-200 Twin-unit apparatus

ACCESSORIES Foaming test

AD0892-A00 Wet test meter

AD0892-A01 Officially certified wet test meter

AD0892-A02 Air pump

AD0892-A03 Glass drying tower

CAL001 PT100 simulator

CAL002 Officially certified PT100 simulator

CONSUMABLES Foaming test

AD0892-C00 Graduate pyrex glass cylinder

AD0892-C01 Rubber stopper with air inlet and outlet

AD0892-C02 Norton spherical Alundum gas diffuser stone (certified for permeability and pore size)

AD0892-C03 Mott stainless steel cylindrical gas diffuser (certified for permeability and pore size)TA012C-N00 ASTM 12C thermometer (-20°C/+102°C)

Specifications may vary without notice.

The Foaming test apparatus is supplied bare without glassware, diffusers, accessories and consumables.

The apparatus consists of a steel frame supporting the control box, the jar and an electric lift that permits to move the stirrer blade up and down in the test cylinder. The speed of the stirrer is continuously showed on a digital tachometer.

- Borosilicate glass jar, 250 mm deep, mounted on a enamel finished benchtop steel frame.

- Anodized aluminium cover with six-position turntable for the insertion of the cylinders containing the samples: a positioning device permits to locate the cylinders exactly below the blade of the sample stirrer, avoiding breakings due to positioning mistakes.

- Electric lifting device for the stirrer support.

- Electric bath stirrer.

- Stainless steel heater.

- Electric sample stirrer.

- Digital tachometer which continuously shows the stirrer speed.

- Electronic timer which automatically stops the sample stirrer after 5 minutes stirring.

- Microprocessor controlled thermoregulator, PID action with built-in digital display 0.1°C accuracy. Probe: PT100 RTD. Regulation accuracy ± 0.1°C.

- Working range: from ambient to 100°C.

- Safety devices against overheating and low-level.

- Easy access control box placed on the right side of the apparatus containing all the electronics: anodized aluminium control panel with english written indications.

- English written user manual.

- For 220 V/50 Hz connections. Power consumption 800 W.

- Dimensions (l x w x h): mm 500 x 460 x 960 approx. Weight: kg 40 approx.

- CE marked.

ACCESSORIES

CAL001 PT100 simulator

CAL002 Officially certified PT100 simulator

CONSUMABLES

AD1401-C00 Graduate cylinder, Pyrex glass

TA009C-N00 ASTM 9C thermometer (-5°C/+110°C)

TA019C-N00 ASTM 19C thermometer (+49°C/+57°C)

TA021C-N00 ASTM 21C thermometer (+79°C/+87°C)

The apparatus consists of a benchtop steel case containing an aluminium thermostatic block with a series of holes for the introduction of the oxidation cells, a support for the flowmeters and a water dispenser for the condenser refrigeration.

- Enamel finished benchtop steel case.

- Aluminium block bath with wells for test tubes.

- Stainless steel electric heaters.

- Microprocessor thermoregulator with built-in temperature display, 0.1°C accuracy. Probe: PT100 RTD. Regulation accuracy ± 0.1°C. Working range: from ambient to 300 °C.

- Safety device against overheating.

- Easy access control box placed on the right side of the apparatus and containing all the electronics and electrical parts. Aluminium control panel with english written indications.

- Oxygen inlet manifold with high precision variable area flowmeters with calibration certificate. Individual needle valves for regulating oxygen flow at 5 ± 0.5 l/h

- Water inlet manifold with valve connections for the mushroom condensers.

- Water outlet manifold.

- English written user manual.

- For connection to 220V/50Hz. Power consumption 2000 W.

- CE marked.

- Four, six, eight and twelve-place units available.

- Version with mass flow controller and software also available.

F53084-100 Four-place unit. Dimensions (l x w x h): 640 x 430 x 1000 mm. Weight: 90 kg

F53084-110 Six-place unit. Dimensions (l x w x h): 760 x 430 x 1000 mm. Weight: 110 kg F53084-120 Eight-place unit. Dimensions (l x w x h): 640 x 490 x 1000 mm. Weight: 130 kg F53084-130 Twelve-place unit. Dimensions (l x w x h): 760 x 430 x 1000 mm. Weight: 160 kg ACCESSORIESCAL001 PT100 simulator

CAL002 Officially certified PT100 simulator

CONSUMABLES

F53084-C00 Test tube

F53084-C01 Allihn condenser

F53084-C02 Oxygen delivery tube

F53084-C03 Set of four copper plates

F53084-C04 Set of four mild carbon steel plates

F53084-C05 Set of four aluminium alloy plates

F53084-C06 Set of four magnesium alloy plates

F53084-C07 Set of four cadmium plated steel plates

F53084-C08 Set of four silver plates

F53084-C09 Set of four solid cadmium plates (non standard)

F53084-C10 Set of four titanium plates (non standard)

F53084-C11 Pack of 10 sheets of abrasive paper 100 grit

F53084-C12 Pack of 10 sheets of abrasive paper 150 grit

F53084-C13 Pack of 10 sheets of abrasive paper 240 grit

F53084-C14 Abrasive powder, 0.5 kg

- Enamel finished aluminium and steel case, benchtop version.

- Dry block heater, two, four or six-place.

- 8.4” touch screen color interface that permits to set block temperature, start/stop tests, enter sample data, diagnose and calibrate temperature and pressure sensor. Temperature digital display with 0.1°C accuracy and +/- 0.1°C regulation accuracy connected to Pt100 RTD. Selectable kPa/psi pressure indicators with 0.1 kPa/psi accuracy: high precision electronic pressure sensors 0 to 2000 kPa scale with 0.1% f.s. accuracy.

- Working range: from ambient to 120°C. Regulation accuracy: ± 0.1°C.

- Stainless steel cartridge heaters, SSR controlled.

- Independent safety device against overheating.

- Oxygen distributor with gage and flexible tube with quick connects for rapid filling of the vessels.

- User friendly graphical software complete with diagnose and calibration routine.

- N° 2 USB ports, n° 1 RS-232 interface and n° 1 Ethernet port on the back panel for the connection to printers or laboratory network.

- English written user manual. CE marked.

- For 220 V/50 Hz connections: 2000 W max power consumption.

- Enamel finished aluminium and steel case, benchtop version.

- Dry block heater, two, four or six-place.

- 8.4” touch screen color interface that permits to set block temperature, start/stop tests, enter sample data, diagnose and calibrate temperature and pressure sensor. Temperature digital display with 0.1°C accuracy and +/- 0.1°C regulation accuracy connected to Pt100 RTD. Selectable kPa/psi pressure indicators with 0.1 kPa/psi accuracy: high precision electronic pressure sensors 0 to 2000 kPa scale with 0.1% f.s. accuracy.

- Working range: from ambient to 120°C. Regulation accuracy: ± 0.1°C.

- Stainless steel cartridge heaters, SSR controlled.

- Independent safety device against overheating.

- Oxygen distributor with gage and flexible tube with quick connects for rapid filling of the vessels.

- User friendly graphical software complete with diagnose and calibration routine.

- N° 2 USB ports, n° 1 RS-232 interface and n° 1 Ethernet port on the back panel for the connection to printers or laboratory network.

- English written user manual. CE marked.

- For 220 V/50 Hz connections: 2000 W max power consumption.

The apparatus consists of a benchtop steel case containing an aluminium thermostatic block with the holes for the introduction of the oxidation cells, a support for the flowmeters and a water dispenser for the condensers refrigeration.

- Enamel finished benchtop steel case.

- Aluminium block bath with wells for test tubes, 48 mm diameter and 365 mm depth.

- Stainless steel heaters.

- Microprocessor thermoregulator with built-in temperature display, 0.1°C accuracy. Probe: PT100 RTD. Regulation accuracy ± 0.1°C. Working range: from ambient to 100 °C.

- Safety device against overheating.

- Easy access control box placed on the right side of the apparatus and containing all the electronics and electrical parts. Aluminium control panel with english written indications.

- Oxygen inlet manifold with high precision flowmeters with calibration certificate. Individual needle valves for regulating oxygen flow at 3 l/h ± 0.1 l/h

- Water inlet manifold with valve connections for the mushroom condensers.

- Water outlet manifold.

- English written user manual.

- For connection to 220V/50Hz. Power consumption 2000 W.

- CE marked.

- Four, six, eight and twelve-place units available.

- Version with mass flow controller and software also available.

AD2274-100 Four-place unit. Dimensions (l x w x h): 760 x 500 x 960 mm. Weight: 90 kg

AD2274-110 Six-place unit. Dimensions (l x w x h): 910 x 500 x 960 mm. Weight: 100 kg AD2274-120 Eight-place unit. Dimensions (l x w x h): 850 x 550 x 960 mm. Weight: 110 kg AD2274-130 Twelve-place unit. Dimensions (l x w x h): 1000 x 550 x 960 mm. Weight: 130 kg ACCESSORIESAD2274-A00 Apparatus for filterable insolubles

AD2274-A01 Pack of 100 filters

AD2274-A02 Vacuum flask 500 ml

CAL001 PT100 simulator

CAL002 Officially certified PT100 simulator

CONSUMABLES

AD2274-C00 Test tube

AD2274-C01 Mushroom condenser

AD2274-C02 Oxygen delivery tube

TA040C-N00 ASTM 40C thermometer (+72°C/+126°C)- Enamel finished benchtop steel case.

- Aluminium block bath with wells for test tubes, 48 mm diameter and 365 mm depth.

- Stainless steel electric heaters.

- Microprocessor thermoregulator with built-in temperature display, 0.1°C accuracy. Probe: PT100 RTD. Regulation accuracy ± 0.1°C. Working range: from ambient to 100 °C.

- Safety device against overheating.

- Easy access control box placed on the right side of the apparatus and containing all the electronics and electrical parts. Aluminium control panel with english written indications.

- Oxygen inlet manifold with high precision flowmeters with calibration certificate. Individual needle valves for regulating oxygen flow at 3 l/h ± 0.1 l/h

- Water inlet manifold with valve connections for the mushroom condensers.

- Water outlet manifold.

- n° 1 thermometer bracket.

- English written user manual.

- For connection to 220V/50Hz. Power consumption 2000 W.

- CE marked.

- Four, six, eight and twelve-place units available.

- Version with mass flow controllers and software also available.

AD0943-100 Four-place unit. Dimensions (l x w x h): 640 x 430 x 1000 mm. Weight: 90 kg

AD0943-110 Six-place unit. Dimensions (l x w x h): 760 x 430 x 1000 mm. Weight: 110 kg AD0943-120 Eight-place unit. Dimensions (l x w x h): 640 x 490 x 1000 mm. Weight: 130 kg AD0943-130 Twelve-place unit. Dimensions (l x w x h): 760 x 430 x 1000 mm. Weight: 160 kg ACCESSORIESAD0943-A00 Winding fixture

CAL001 PT100 simulator

CAL002 Officially certified PT100 simulator

CONSUMABLES

AD0943-C00 Test tube

AD0943-C01 Mushroom condenser

AD0943-C02 Oxygen delivery tube

AD0943-C03 Cell thermometer

AD0943-C04 Syringe sampling tube

AD0943-C05 Methacrylate sampling tube holder

AD0943-C06 Sampling tube spacer

AD0943-C07 Catalyst coil

AD0943-C08 Steel wire, 10 m

AD0943-C09 Copper wire, 10 m

TA040C-N00 ASTM 40C thermometer (+72°C/+126°C)

Specifications may vary without notice.

- Enamel finished benchtop steel case.

- Aluminium block bath with jackets 27 mm diameter and 140 mm height for oxidation tubes.

- Stainless steel heaters.

- High efficiency thermal insulation.

- Microprocessor thermoregulator, PID action with built-in digital display 0.1°C accuracy. Probe: Pt100 RTD For working temperature from ambient to 220°C ± 0.1°C.

- Safety device against overheating.

- Easy access control box containing all the electronics. Anodized aluminium control panel with English written indications.

- For 220 V/50 Hz connection. Power consumption: 1500 W.

- English written user manual.

- CE marked.

- Without glassware and flowmeters: appropriate flowmeter rack should be selected from the table in accessories section.

- Glassware support to run tests acc. to CEI 10.8, CEI/IEC 1125, EN 61125 IP 48, 280, 306, 307, EN 61125 also available.

- Software for flow control included in the digital flowmeter racks.

AD2440-200 Four-place apparatus.

AD2440-210 Six-place apparatus.

AD2440-220 Eight-place apparatus.

AD2440-230 Twelve-place apparatus.

ACCESSORIES

AD2440-A00 Rack with four high precision flowmeters with precision valve at inlet, 0 to 20 l/h air, 150 mm scale (IP 280)

AD2440-A01 Rack with six flowmeters as above

AD2440-A02 Rack with eight flowmeters as above

AD2440-A03 Rack with twelve flowmeters as above

AD2440-A04 Rack with four high precision flowmeters with precision valve at inlet, 0 to 1.6 l/h oxygen, 150 mm scale (CEI 10.8, CEI/IEC 1125 (A + B), EN 61125 (A + B), IP 48, 306, 307

AD2440-A05 Rack with six flowmeters as above

AD2440-A06 Rack with eight flowmeters as above

AD2440-A07 Rack with twelve flowmeters as above

AD2440-A10 Adsorption tube support for tests acc. to CEI 10.8, CEI/IEC 1125, EN 61125, IP 48, 280, 306, 307

AD2440-A20 Rack with four high precision digital flowmeters with software, 0 to 21 l/h air (IP 280)

AD2440-A21 Rack with six digital flowmeters as above

AD2440-A22 Rack with eight digital flowmeters as above

AD2440-A23 Rack with twelve digital flowmeters as above

AD2440-A24 Rack with four high precision digital flowmeters with software, 0 to 1.8 l/h oxygen, (CEI 10.8, CEI/IEC 1125 (A + B), EN 61125 (A + B), IP 48, 306, 307)

AD2440-A25 Rack with six digital flowmeters as above

AD2440-A26 Rack with eight digital flowmeters as above

AD2440-A27 Rack with twelve digital flowmeters as above

CAL001 PT100 simulator

CAL002 Officially certified PT100 simulator

CONSUMABLES

AD2440-C00 Oxidation tube with Drechsel head

AD2440-C01 Adsorption tube with Drechsel head

AD2440-C02 Set of 12 copper coils for tests acc. to ASTM D 2440

AD2440-C03 Set of 12 copper coils for tests acc. to IP 306 and IP 307

AD2440-C04 Set of 12 copper coils for tests acc. to CEI/IEC 1125 (method A) and EN 61125 (method A)

AD2440-C05 Set of 12 copper coils for tests acc. to CEI/IEC 1125 (method B) and EN 61125 (method B)

Specifications may vary without notice.

- Enamel finished steel case, benchtop version.

- Stainless steel tank. Capacity: 70 liters.

- Stainless steel top cover.

- One support rack for the vessels.

- Electric stirrer to ensure temperature uniformity.

- Microprocessor controlled thermoregulator with PID action and built-in digital display 0.1 °C accuracy. Probe: Pt100 RTD. Regulation accuracy: ± 0.1°C.

- Working range: from ambient to 170°C.

- Stainless steel heaters, SSR controlled.

- Independent motor for each vessel, inverter controlled.

- Safety devices against overheating and low level.

- Signal conditioning board: it provides to transform the signals coming from the vessels into the RS-232C serial protocol making the apparatus connectable to a PC through serial port.

- Software running under Windows Xp/Vista/7 that shows on separate graphs the pressure data coming from the vessels and the temperature of the heating bath. Data are stored on the hard disk in .TXT file format and can be retrieved, compared and printed. Diagnostic and calibration routines permits to accurately verify and calibrate temperature, pressure and rotation speed.

- English written user manual. CE marked.

- For 220 V/50 Hz connections: 4000 W power consumption.

AD2272-100 Apparatus. Dimensions: 750 x 750 x 980 mm. Weight: 150 kg

ACCESSORIES RPVOT / TFOUT Turbine oils

AD2272-A00 Rotating vessel, AISI 316 stainless steel

AD2272-A01 Table support with swivelling castors

PC01 Desktop PC

PRN01 Printer

CAL001 PT100 simulator

CAL002 Officially certified PT100 simulator

CONSUMABLES RPVOT / TFOUT Turbine oils

AD2272-C00 Gasket for vessel

AD2272-C02 Glass sample containerAD2272-C03 PTFE disc

AD2272-C04 Set of n°10 Copper coil

AD2272-C05 Spring

AD4742-C00 Glass sample container with PTFE disc for ASTM D 4742

AD4742-C01 Aluminium spacer

TA037C-N00 IP 37C thermometer (+144°C/+156°C)

TA102C-N00 ASTM 102C thermometer (+123°C/+177°C)

The softening point is the temperature at which a disk of the sample held within a horizontal ring is forced downward a distance of 25.4 mm under the mass of a steel ball as the sample is heated at a prescribed rate in a water or glycerine bath. The apparatus is a benchtop model which houses the components and a Panel PC with touch screen. A software running under Microsoft Windows Xp permits to select the test method and the test parameters, run the test automatically, store, retrieve and print data, diagnose and calibrate the instrument offering in the meanwhile all the features of Windows systems such as LAN connectivity. Besides, a unique cooling system, not fitted on other instruments permits to quickly cool down the sample allowing to handle the glassware and to perform a greater number of tests during a day by reducing the dead times between two analysis. The apparatus is suitable also to test coating mixtures and other materials different from bitumen.

- Enamel finished steel case.

- Pyrex beaker 1000 cc capacity for sample heating.

- Electric lifting device.

- Stainless steel sample support for up to two samples.

- Two brass ASTM rings, two centering devices and two steel balls.

- Electric stirrer with variable speed for the liquid bath: it can be excluded by turning off a switch on the control panel.

- Stainless steel heater.

- Brass cooling coil: tap water is used as cooling media and a solenoid valve is automatically opened by the controller when the test finishes.

- PC based controller with colour touch-screen interface.

- Photocell detector for softening point.

- Software characteristics: selection of the media used during the test, introduction of the test parameter through the touch-screen, selectable cooling time, storage of up to 400 test results and possibility of retrieve and print test reports, LAN connectivity, calibration and diagnostic routines.

- English written user manual.

- For 220 V/50 Hz connection: 800 W power consumption.

- Dimensions (l x w x h): mm 380 x 450 x 720 approx. Weight 40 Kg approx.

- CE marked.

AD0036-600 Apparatus

ACCESSORIES

AD0036-A00 Sample support

CAL001 PT100 simulator

CAL002 Officially certified PT100 simulator

CONSUMABLES

AD0036-C00 Pyrex beaker

AD0036-C01 ASTM/IP ring

AD0036-C03 Centering ring

AD0036-C04 Steel ball

- Enamel finished steel case, benchtop version.

- Electric heating plate.

- Brass oil cup with insulating handle (n°1 Pt100 with cable and quick connector supplied with the instrument).

- Electronically driven mechanism that passes the flame over the cup at the correct intervals for the correct amount of time: electric pilot flames in conjunction with a solenoid valve on the gas line automatically light the flame and relight in case it extinguishes during the test.

- Second generation ionization flash sensor.

- Flame extinguisher: automatically extinguishes the flame covering the cup in case a fire is detected or after fire point detection.

- PC based controller with touch-screen interface.

- Software characteristics: selection of the ASTM/IP test method or setup of up to 40 custom methods, introduction of the test parameters through the touch screen, possibility to change the setpoint during the test, “search” option (for sample with unknown flash point), selectable cooling time, storage of up to 400 test results and possibility to retrieve and print test reports, LAN connectivity, calibration and diagnostic routines.

- LAN connectivity: the apparatus can be connected directly to a hub to become part of the user network: a software supplied with the apparatus permits to retrieve data also from another PC.

- Flash and fire point detection through ionization sensor: the apparatus also provides an alert if a flash has occurred at the first flame application, warning that the test result is not reliable. The flash point temperature remains shown on the display until the operator’s acknowledgement.

- Safety device is provided to stop the analyzer if a flash has not been detected at a temperature 30°C over the preset value or at a temperature of 400°C. This safety device could be excluded to perform "search" tests.

- English written user manual. Microsoft Windows original license.

- Dimensions (l x w x h): mm 360 x 460 x 680. Weight: kg 36 approx.

- For 220 V/50 Hz connections: 600 W power consumption.

- CE marked.

AD0092-600 Apparatus

ACCESSORIES

AD0092-A00 Printer

CAL001 PT100 simulator

CAL002 Officially certified PT100 simulator

CONSUMABLES

AD0092-C00 Oil cup

AD0092-C02 Pt100 probe

AD0092-C03 Electric ignitor

The apparatus consists of a constant temperature bath capable to work in the range from -10 to 40 °C (thanks to a built-in cooling compressor) with an electrically powered tractor that pulls apart at an selectable speed the two ends of two briquet specimens: a load cell records continuously the force applied to the briquets transmitting them plus the bath temperature and the carriage speed to a PC through the RS-232 serial interface or USB port (converter required): a data acquisition software permits to display data on graphs, store them on the hard-disk, obtain printed reports and calibrate temperature, force and elongation sensors

- Enamel finished steel case, floor mounted with swivelling castors.

- Stainless steel bath, thermally insulated, with drain valve.

- Chromium plated brass pump: it provides an adequate stirring of the liquid in the bath. Switch to turn it off during the test.

- Stainless steel heater.

- Microprocessor thermoregulator with PID action: built-in digital display 0.1°C accuracy. Probe: Pt100 RTD. Working range: from -10 to 40°C.

- Safety device against overheating and low level with alarm lamp.

- Built-in hermetic cooling compressor.

- Acrylic hinged cover: it helps to maintain a constant temperature in the bath providing a clear view of the inside.

- Traction carriage with variable speed motor: the carriage can contain 2 briquet molds. Automatic stop safety switch that stops the carriage when the maximum elongation has been reached. Traction length: 50, 100 or 150 cm.

- White PTFE screen fixed to the bottom of the bath: it permits a better vision of the test while in execution.

- Two load cells mechanically connected to the briquet molds. Range: 0 - 200 Newton: accuracy: 0.5 Newton.

- RS-232 serial interface for the connection to a PC: we can supply the instrument with a traditional desktop PC or the user can use one of his PC’s with the requirements reported in the “accessories” section here below.

- Data acquisition software running under Windows Xp/Vista/7: the software provides to record and show on graphs the force applied to the briquet molds, the elongation and the temperature of the bath. Data can be stored on a hard disk and printed. Software routines for calibration of temperature, force and elongation sensors.

- Easy access control box containing all the electronics: anodized aluminium control panel with english written indications.

- English written user manual with installation instructions.

- For 220 V/50 Hz connections: 1800 W power consumption.

- Dimensions (l x w x h): mm 1800 x 450 x 1300 approx. (100 cm version) 2400 x 450 x 1300 approx. (150 cm version). Weight: 250 kg approx.

- CE marked.

AD0113-500 Apparatus, 500 mm traction length

AD0113-510 Apparatus, 1000 mm traction length

AD0113-520 Apparatus, 1500 mm traction length

ACCESSORIES

AD0113-A00 Mold acc. to ASTM D 113 - IP 32 - IS 1208

AD0113-A01 Brass plate for mold assembling

AD5976-A00 Mold acc. to ASTM D 5976

PC01 Desktop PC

PRN01 Printer

CAL001 PT100 simulator

CAL002 Officially certified PT100 simulator

USB-CONV RS232 to USB converter

The apparatus consists of a penetrometer with adjustable head combined with a gear that permits a fine adjustment of the cone position right upon the bitumen sample: the results are showed on a digital display placed, together with an electronic timer in an independent control box.Optionally, refrigerated baths of various sizes are available (please require related technical bulletin): by connecting the bath to the transfer dish it is possible to penetrate samples while immersed in water at 25°C or other test temperatures.

- Robust flat aluminium base with centering device, spirit level and levelling screws.

- Encoder with 50 mm motion for penetration measurement.

- Digital penetration display with 1/10 mm accuracy.

- Electronic programmable timer for penetration time setting.

- Stainless steel cone plunger (47.5 g total weight) complete with electromechanical locking system. By pushing the start button the locking system is disabled: after the preset time (usually 5 seconds) the plunger is automatically locked in the reached position and the distance (penetration) from the top surface of the sample is shown on the display.

- Standard ASTM/IP needle, 2.5 g total weight.

- One 50 g and one 100 g load weights.

- Button for manual handling of the plunger.

- Mirror and spot light.

- Easy access control box which contains all the electronics: anodized aluminium control panel with English written indications.

- English written user manual.

- For 220 V/50 Hz connections. Power consumption 50 W.

- Dimensions (l x w x h): mm 350 x 325 x 350 approx. Weight: kg 15 approx.

- CE marked.

AD0005-100 Digital penetrometer for bitumens

ACCESSORIES

AD0005-A00 Transfer dish

AD0005-A01 Brass sample container, Ø 70x45 mm

AD0005-A02 Brass sample container, Ø 55x35 mm

AD0005-A03 Penetration measurement calibration block

CONSUMABLES

AD0005-C00 Needle acc. to ASTM D 5

AD0005-C01 Load weight 50 g

AD0005-C02 Load weight 100 g

AD0005-C03 Stainless steel plunger, 47.5 g

The apparatus consists of a constant temperature bath capable to work in the range from -10 to 40 °C (thanks to a built-in cooling compressor) with an electrically powered tractor that pulls apart at a determined speed the two ends of two briquet specimens: the elongation is measured by means of a pointer on the tractor and a graduated scale fixed to the cover.

- Enamel finished steel case, floor mounted with swivelling castors.

- Stainless steel bath thermally insulated: complete with drain valve.

- Chromium plated brass pump: it provides an adequate stirring of the liquid in the bath.

- Stainless steel heater.

- Microprocessor thermoregulator with PID action: built-in digital display 0.1°C accuracy. Probe: Pt100 RTD. Working range: from -10 to 40°C.

- Safety device against overheating and low level with alarm lamp.

- Built-in hermetic cooling compressor: CFC/HCFC-free gas.

- Acrylic hinged cover: it helps to maintain a constant temperature in the bath providing a clear view of the inside.

- Traction carriage with two-speed motor for 10 and 50 mm/min: the carriage supports 2 briquet molds. Automatic stop safety switch that stops the carriage when the maximum elongation has been reached. Traction length: 50, 100 or 150 cm.

- White screen fixed to the bottom of the bath: it permits a more clear vision of the elongated specimen during the test.

- Easy access control box containing all the electronics: anodized aluminium control panel with english written indications.

- English written user manual with installation instructions.

- For 220 V/50 Hz connections: 1800 W power consumption.

- Dimensions (l x w x h): mm 1800 x 450 x 1300 approx (AD0113-200) mm 2400 x 450 x 1300 approx (AD0113-250). Weight: 250 kg approx.

- CE marked.

AD0113-100 Apparatus, 50 cm traction length

AD0113-110 Apparatus, 100 cm traction length

AD0113-120 Apparatus, 150 cm traction length

ACCESSORIES

AD0113-A00 Mold acc. to ASTM D 113 - IP 32 - IS 1208

AD0113-A01 Brass plate for mold assembling

AD5976-A00 Mold acc. to ASTM D 5976

CAL001 PT100 simulator

CAL002 Officially certified PT100 simulator

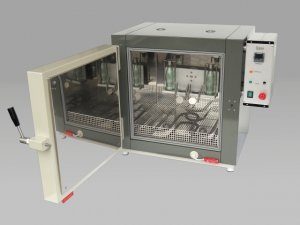

The apparatus consists of a convection oven manufactured as described in the ASTM E 145 specification (type IB), suitable for temperatures up to 180°C and equipped with a rotating shelf inside. An electronic controlled motor with gear reducer mounted on the top of the oven rotates the shelf at 5.5 rpm.

- Enamel finished steel case, benchtop model.

- Stainless steel interior with plenum fan for air circulation. Internal dimensions 380 x 380 x 380 mm. High efficiency thermal insulation.

- Stainless steel heater.

- Hinged door fitted with double wall window 300 x 200 mm, for internal view.

- Two openings, one on the bottom and one on the top for ventilation.

- Anodized aluminium horizontal rotating shelf 300 mm diameter, capable of supporting nine ASTM D 6 or three ASTM D 1754 sample containers. The shelf is suspended by a vertical shaft, centered with the horizontal interior dimensions and vertically located in the centre of the oven.

- Electronic controlled motor, 1/4 HP with built-in gear reducer that provides to rotate the shelf at a speed of 5.5 rpm.

- Microprocessor controlled thermoregulator with PID action and built-in digital display, 0.1°C accuracy. Probe: Pt100 RTD. Working range: from ambient to 180°C ± 1°C.

- Safety device against overheating.

- Easy access control box containing all the electronics: anodized aluminium panel with English written indications.

- English written user manual with installation instructions.

- For 220 V/50 Hz connections: 2000 W power consumption.

- Dimensions: 900 x 700 x 900 mm approx. Weight: 110 Kg approx.

- CE marked.

AD0006-100 Apparatus

ACCESSORIES

AD0006-A00 ASTM D 6 container

AD1754-A00 ASTM D 1754 container

AD1754-A01 ASTM D 1754 rotating shelf

CAL001 PT100 simulator

CAL002 Officially certified PT100 simulator

CONSUMABLES

TA013C-N00 ASTM 13C thermometer (+155°C/+170°C)

The apparatus consists of a benchtop steel case supporting the electrical heater, the gas ignitor and the thermometer support.

- Enamel finished benchtop steel case.

- Electric heating plate with stainless steel support.

- Electronic temperature regulator with dial on the front panel.

- Oil cup, brass with insulating handle.

- Gas ignitor, stainless steel, complete with valve and with support that permits to pass the flame over the cup at the correct distance.

- Pt100 probe for temperature acquisition.

- Support for Pt100 probe.

- Digital display for sample temperature, 0.1°C accuracy.

- English written user manual.

- For 220 V/50 Hz connections, 500 W power consumption.

- Dimensions (l x w x h): mm 360 x 360 x 300. Weight: 8 kg approximately.

- CE approved.

AD0092-110 Apparatus with digital display, 0.1°C accuracy (complete with PT100 RTD with cable and connector)

ACCESSORIES

CAL001 PT100 simulator

CAL002 Officially certified PT100 simulator

CONSUMABLES

AD0092-C00 Oil cup

AD0092-C01 PT100 probe

TA011C-N00 ASTM 11C thermometer (-6°C/+400°C)

RTFOT test is used to determine the effect of heat and air on a moving film of semi-solid asphaltic materials. The effects of this treatment are determined from measurements of the properties of the asphalt before and after having heated in a oven for 75 minutes at 163°C a moving film of asphaltic material while air at a rate of 4 l/min is directed against the sample. The apparatus consists of a forced air circulation oven suitable for temperatures up to 180°C and equipped with a rotating shelf placed inside along with a coil that preheats the air directed into the sample container.

- Enamel finished steel case benchtop version.

- Stainless steel inside walls with 38 mm air plenum. Glass wool and ceramic fibers heating insulation.

- Door with double tempered glass window for internal view.

- Chromium plated coiled air line, 8 mm diameter and 7.6 m long, with 1 mm diameter orifice. The orifice is placed 8 mm from the opening of the glass containers.

- Adjustable flowmeter for the regulation of the air jet inside the oven: the flowmeter is complete with a regulation valve and is placed on the left side of the case.

- Squirrel cage fan, 135 mm diameter and 75 mm height, placed at a midpoint in the width of the oven and 150 mm from the face of the carriage. The speed of the fan is electronically regulated at 1725 rpm: fan motor disposed externally.

- Vertical circular aluminium carriage 300 mm diameter, placed 160 mm from the upper inside wall of the oven, excluding the air plenum, and 110 mm from the rear inside wall. The carriage is equipped with stainless steel clips for firmly holding eight glass containers.

- The location of the thermometer support permits to check the thermometer through the door window during the test.

- Electronically controlled motor with reducing gear for a 15 rpm precise carriage rotation.

- Microprocessor controlled thermostat with PID action with built-in digital display 0.1°C accuracy showing the set point and the current temperature inside the oven. Probe: Pt100 RTD. For working temperature of 163°± 0.5° C.

- Safety device against overheating.

- Safety device that stops the carriage in case the door is opened during the test.

- English written user manual.

- For 220 V/50 Hz connections: 2200 W power consumption.

- Dimensions (l x w x h): mm 940 x 890 x 910 approx. Weight: 115 kg approx.

- CE marked.

AD2872-100 Apparatus

ACCESSORIES RTFOT

AD2872-A00 Glass sample container

CAL001 PT100 simulator

CAL002 Officially certified PT100 simulator

CONSUMABLES RTFOT

TA013C-N00 ASTM 13C thermometer (+155°C/+170°C)

- Enamel finished benchtop steel case.

- Stainless steel inside tank, 10 liter capacity, thermally insulated.

- Stainless steel cover.

- Electric pump with overload protection. The pump is equipped also with a propeller to stir the liquid in the tank.

- Stainless steel heater.

- Air cooled hermetically-sealed single stage cooling compressor placed aside the tank. Chromium plated cooling coil. CFC/HCFC-free gas is used to fill the circuit.

- Microprocessor thermoregulator with PID action and built-in digital display 0.1 °C accuracy. Probe: Pt100 RTD. The heater is piloted through a SSR.

- Safety device against over-temperature and low-level: it cut off the power supply and light a lamp on the control panel in case of alarm.

- 3 m thermally insulated tubing to connect to the transfer dish.

- Easy access control box containing all the electronics: anodized aluminium panel with English written indications.

- English written user manual.

- For 230 V/50 Hz connection. Power consumption: 500 W approx.

- Dimensions (l x w x h): 500 x 400 x 500 mm approx. Weight: 25 kg approx.

AD0005-200 Apparatus ACCESSORIES CAL001 PT100 simulator CAL002 Officially certified PT100 simulator

The apparatus consists of a case containing a stainless steel bath and supporting precision flowmeters. The bath is equipped with a stainless steel cover with holes for the introduction of the evaporation cells.

- Enamel finished benchtop steel case.

- Stainless steel bath with drain valve. High efficiency thermal insulation.

- Electric stirrer with stainless steel shaft and propeller.

- Stainless steel heaters.

- Stainless steel cell support.

- High precision flowmeters with needle valve and complete with calibration certificate. For a flow rate of 2 l/min.

- Air filter containing glass wool.

- Microprocessor thermoregulator with PID action: built-in digital thermometer 0.1°C accuracy. Probe: Pt100 RTD. Test range: from ambient to 160°C.

- Safety device against overheating and low-level.

- English written user manual.

- For 220 V/50 Hz connection. Power consumption 2000 W.

- Dimensions (l x w x h): mm 800 x 400 x 700 approx. Weight: kg 45 approx. (four-unit version).

- CE marked.

- Two and four place units available

- Version with mass flow controllers and software also available.

ACCESSORIES

AD0972-A00 Stainless steel cell with copper coil for air heating

AD0972-A01 Test cup for oil

AD0972-A02 Test cup for grease

CAL001 PT100 simulator

CAL002 Officially certified PT100 simulator

CONSUMABLES

TA022C-N00 ASTM 22C thermometer (+95°C/+103°C)

TA067C-N00 ASTM 67C thermometer (+95°C/+155°C)

Worked penetration results may be used to establish the consistency of lubricating greases after prolonged working. The change in worked penetration results on a grease after prolonged working are believed to be a measure of its shear stability under the conditions of the test.The electrically operated grease working machine consists of a geared motor for 60 strokes/min mounted on a aluminium base with clamps to fix the grease workers. The number of strokes, continuously showed on a display, can be preset to stop the worker after any required number of strokes up to 100,000.

- Cast aluminium base, machine worked and enamel finished. Benchtop version.

- Geared motor unit for 60 strokes/min.

- Two crank flanges, cast iron.

- Programmable counter with six digits.

- Two grease workers.

- Two worker plates, 51 holes.

- Wrench for opening and closing of grease workers.

- For 380V / 50Hz connections: 600 W power consumption.

- English written user manual.

- Dimensions (l x w x h): mm 450 x 450 x 350 approx. Weight: kg 30 approx.

- CE marked.

- Single and dual units available.

AD0217-100 Single-unit grease working machine

AD0217-110 Dual-unit grease working machineACCESSORIES

AD0217-A00 Worker plate, 51 holes

AD0217-A01 Worker plate, 270 holes (FTMS 313.3)

AD0217-A02 Lip seal for rod

AD0217-A03 Overflow ring

AD0217-A04 Blank cup cover (used when preheating the sample prior to test)

- Enamel finished benchtop steel case.

- High efficiency thermal insulation to avoid heating of the external case.

- Aluminium block with holes for the introduction of the cell.

- Air preheater inserted in the bottom of the block, one for each position: each preheater is independently regulated through an electronic voltage variator.

- Stainless steel band heaters.

- Covers, air eduction tubes hoods and cups, stainless steel. Kalrez gaskets.

- Digital displays (one for each position) for the indication of the temperature of the air coming out from the cells. Probe: type K thermocouple (also supplied).

- High precision flowmeters with needle valve and complete with calibration certificate, 0-3 l/min scale.

- Air filter fixed on the case and containing glass wool.

- Microprocessor thermoregulator wiith PID action: built-in digital thermometer 0.1°C accuracy. Pt100 probe. Test range: from ambient to 316°C.

- Safety devices against overheating.

- English written user manual.

- For 220 V/50 Hz connection. Power consumption 2000 W.

- Dimensions (l x w x h): mm 860 x 730 x 520 approx. Weight: kg 100 approx. (2-place version)

- CE approved.

- Two and four-place units available

ACCESSORIES

AD2595-A00 Digital thermometer

CONSUMABLES

AD2595-C00 Type K thermocouple with supports (for air temperature measurement)AD2595-C01 Cover and eduction tube

AD2595-C02 Sample cup with hood

AD2595-C03 Gasket

TA003C-N00 ASTM 3C thermometer (-5/+400°C)

The apparatus consists of a benchtop case containing an aluminium block and the electronics: a touch screen interface on the front permits to control the equipment. Temperature and pressure data are graphically shown and can be retrieved or printed: the software comprehends also a diagnostic and calibration routine. Vessels are equipped with a pressure transducer and a quick connect cable for the connection to the instrument: an oxygen line consisting of a flexible tube with valve and gage permits loading operations.

- Enamel finished aluminium and steel case, benchtop version.

- Dry block heater, two, four or six-place.

- 8.4” touch screen color interface that permits to set block temperature, start/stop tests, enter sample data, diagnose and calibrate temperature and pressure sensor. Temperature digital display with 0.1°C accuracy and +/- 0.1°C regulation accuracy connected to Pt100 RTD. Selectable kPa/psi pressure indicators with 0.1 kPa/psi accuracy: high precision electronic pressure sensors 0 to 2000 kPa scale with 0.1% f.s. accuracy.

- Working range: from ambient to 120°C. Regulation accuracy: ± 0.1°C.

- Stainless steel cartridge heaters, SSR controlled.

- Independent safety device against overheating.

- Oxygen distributor with gage and flexible tube with quick connects for rapid filling of the vessels.

- User friendly graphical software complete with diagnose and calibration routine.

- N° 2 USB ports, n° 1 RS-232 interface and n° 1 Ethernet port on the back panel for the connection to printers or laboratory network.

- English written user manual. CE marked.

- For 220 V/50 Hz connections: 2000 W max power consumption.

AD0942-600 Apparatus for two vessels, aluminium block. Dimensions: 600 x 760 x 770 mm. Weight: 80 kg.

AD0942-610 Apparatus for four vessels, aluminium block. Dimensions: 600 x 760 x 770 mm. Weight: 110kg.

AD0942-620 Apparatus for six vessels, aluminium block. Dimensions: 650 x 760 x 770 mm. Weight: 130kg.

ACCESSORIES

AD0942-A00 Oxidation vessel complete with valve, bursting disk, pressure transducer head cable and connector

AD0942-A01 Stainless steel dish holder

PRN01 Printer

CAL001 PT100 simulator

CAL003 Official Certificate for Pt100 simulator

CONSUMABLESAD0942-C00 Gasket for vessel

AD0942-C01 Glass sample container

TA022C-N00 ASTM 22C thermometer (+95°C/+103°C)

The apparatus consists of a benchtop case with a hinged shield that covers the rolling mechanism vane. Two and four-cylinder units are available.

- Enamel finished benchtop steel case.

- Upper vane hosting the rolling mechanism ball bearing mounted. Aluminium bearing supports.

- Thermally insulated hinged cover with safety switch that stops the roller motor, fan and heater when opened.

- Microprocessor thermoregulator with built-in digital display 0.1°C accuracy. Probe: Pt100 RTD. Working range: from ambient to 100 +/- 1°C.

- Safety device against overheating.

- Stainless steel heater.

- Fan for air circulation inside the cylinder vane.

- Set of stainless steel cylinders with threaded caps and 5 kg brass roller weights.

- Electronic timer that stops the test at the end of the preset time. Buzzer that sounds to alert that test is completed.

- Electronically driven motor for operation at 10 and 165 rpm. Thermally protected against overload.

- Control box containing all the electronics.

- English written user manual.

- For 220 V/50 Hz connections: 1000 W power consumption.

- Four-cylinder apparatus also available.

- CE marked.

AD1831-100 Two-cylinder apparatus. Dimensions (l x w x h): mm 500 x 400 x 400. Weight: 55 kg

AD1831-110 Four-cylinder apparatus. Dimensions (l x w x h): mm 500 x 650 x 400. Weight: 80 kg

ACCESSORIES

AD1831-A00 Cylinder with threaded caps

AD1831-A01 Roller weight, 5 kg

CAL001 PT100 simulator

CAL002 Officially certified PT100 simulator

- Enamel finished benchtop steel case.

- Stainless steel inside tank, 10 liter capacity, thermally insulated.

- Stainless steel cover.

- Electric pump with overload protection. The pump is equipped also with a propeller to stir the liquid in the tank.

- Stainless steel heater.

- Air cooled hermetically-sealed single stage cooling compressor placed aside the tank. Chromium plated cooling coil. CFC/HCFC-free gas is used to fill the circuit.

- Microprocessor thermoregulator with PID action and built-in digital display 0.1 °C accuracy. Probe: Pt100 RTD. The heater is piloted through a SSR.

- Safety device against over-temperature and low-level: it cut off the power supply and light a lamp on the control panel in case of alarm.

- 3 m thermally insulated tubing to connect to the transfer dish.

- Easy access control box containing all the electronics: anodized aluminium panel with English written indications.

- English written user manual.

- For 230 V/50 Hz connection. Power consumption: 500 W approx.

- Dimensions (l x w x h): 500 x 400 x 500 mm approx. Weight: 25 kg approx.

AD0005-200 Apparatus ACCESSORIES CAL001 PT100 simulator CAL002 Officially certified PT100 simulator

The apparatus consists of a benchtop case supporting the motor, the bath, the pump and the water pipes. All the electronics is contained in a control box fixed to the instrument body.

- Enamel finished benchtop steel case.

- Test bearing housing and shield manufactured exactly as specified in the method.

- Stainless steel reservoir complete with inlet and outlet lines, aluminium housing mount, chromium plated brass circulating pump, 1/4 HP electric driving motor with belts;

- Stainless steel cartridge heater.

- Microprocessor thermoregulator with built-in digital display 0.1°C accuracy. Probe: Pt100 RTD. Working range: from ambient to 100°C. Suitable for working at 37.8 ± 0.1°C and 79 ± 0.1°C;

- Motor and pulleys for operation at 600 ± 30 rpm;

- The motor and pulley arrangement permits to start the water pump without starting the bearing for water flow calibration;

- Regulation and by-pass valve to regulate the flow at 5 ± 0.5 ml/sec through a 1 mm capillary;

- English written user manual.

- For 220 V/50 Hz connections: 600 W power consumption;

- Dimensions: mm 400 x 400 x 600. Weight: 25 kg.

- CE marked.

AD1264-100 Apparatus

ACCESSORIES

CAL001 PT100 simulator

CAL002 Officially certified PT100 simulator

CONSUMABLES

AD1264-C00 Test bearing type 6204

TA015C-N00 ASTM 34C thermometer (+25°C/+105°C)

The apparatus consists of a benchtop case containing all the electronics and supporting the front-wheel hub and spindle assembly encased in a thermostatically controlled air bath. The motor is placed in the rear and rotates the spindle at 660 rpm through a V-belt drive.

- Enamel finished benchtop steel case. Hinged shield with thermal insulation. Safety switch that stops the motor and the heating when the shield is open.

- Stainless steel bearing spindle fixed to the body with insulating spacers. Jacket for ASTM 7C spindle thermometer.

- Stainless steel hub with aluminium driven pulley and leakage collector.

- One Timken n° 15118 bearing with n° 15250 cup.

- One Timken n° 9074 bearing with n° 9196 cup.

- 1/3 HP electric motor with metal shaft extension, drive pulley and fan built exactly as prescribed by the ASTM D 1263 test method. The motor is mounted on an adjustable support to permit tightening the pulley.

- Stainless steel heaters.

- Microprocessor thermostat with PID action and built-in digital display 1°C accuracy. Probe: Pt100 RTD.

- Working range: from ambient to 165 °C. Regulation accuracy: +/- 1°C.

- Safety devices against overheating.

- Digital timer for the operation time regulation: it stops the spindle automatically after the preset time has elapsed.

- For 220 V/50 Hz connections: 1700 W power consumption.

- English written user manual.

- CE marked.

- Dimensions (l x w x h): 550 x 450 x 380 mm. Weight: 70 kg.

AD1263-100 Apparatus