Corrosion of Cast Aluminium Alloys

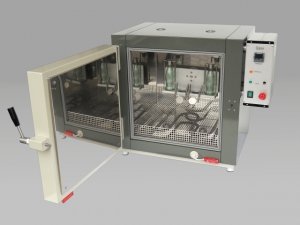

The apparatus consists of a base supporting one or two heat-transfer corrosion cells. Cells are rated for a working pressure up to 40 psi and working temperature up to 160 °C. An electronic timer permits to set the test duration while an electronic thermostat is used to control the temperature.

- Enamel finished benchtop steel base.

- Safety screen surrounding the cell(s).

- Heat transfer corrosion cell composed by a Pyrex-glass cell with stainless steel top and bottom plates.

- Stainless steel heat transfer bar. 950 W coaxial heater piloted through a solid state relay.

- Stainless steel manifold mounted on the top plate and equipped with purge valve, pressure relief valve and gage.

- Filling nozzle with cap on the top plate.

- Four stainless steel rods for assembly.

- Electronic thermoregulator with PID action and built-in digital display. Probe: type K thermocouple. In the twin-unit, an independent thermostat for each position is adopted.

- Working range: from ambient to 160°C.

- Safety device against overheating.

- Electronic timer: it is possible to preset the test duration. When the preset time is elapsed, the heater is automatically turned off. In the twin-unit, an independent timer for each position is adopted.

- English written user manual.

- For 220 V/50 Hz connections. Power consumption: 2200 W (twin unit) and 1100 W (single unit).

- Dimensions (l x w x h): 800 x 350 x 850h mm (twin unit) and 450 x 350 x 850h mm (single unit).

- CE marked.

AD4340-100 Single-unit apparatus

AD4340-110 Double-unit apparatus

ACCESSORIES

CAL001 PT100 simulator

CAL002 Officially certified PT100 simulator

CONSUMABLES

AD4340-C00 Specimens

AD4340-C01 Pyrex glass cell

AD4340-C02 Viton gasket

AD4340-C03 Type K thermocouple