SCT-D Stress Crack Tester (26 Positions) – For testing the Stress Crack Resistance of Carbonated Soft Drink Bottles

The AT2E SCT-D Stress Crack Tester is designed to test the internal stress in bottle base and for determining the stress crack resistance of blow-molded PET carbonated soft drink bottles by measuring the propensity for base cracking upon exposure to an aqueous sodium hydroxide solution under a controlled environment, so that to estimate the long term behavior of bottles.

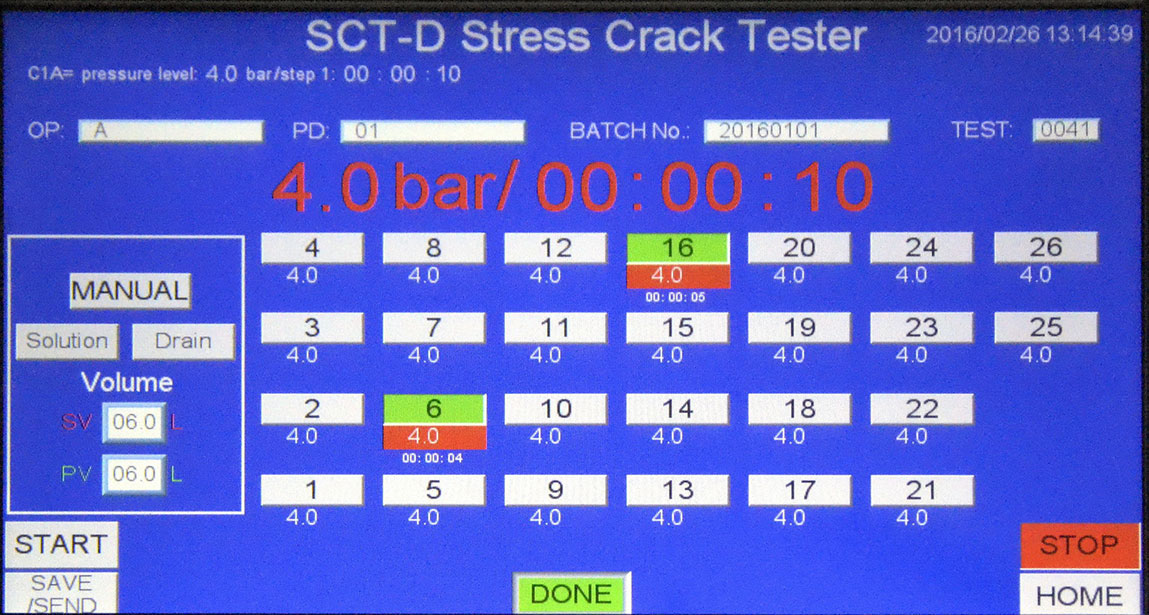

As per the above screen shot, during the test, the bottles in #6 and #16 positions leak, the lights of positions #6 and #16 will become green automatically and system will stop pressurizing the corresponding positions.

Or, operator can press the position button to stop pressurizing if any tiny leakage occurs by observation. Leak pressure value and time will be displayed below the button.

System will also generate a data table for each test to record the test pressure of each position. In the table, position with green light will be displayed as “NG” with the leakage pressure value. Normal position will be displayed as “OK” with the predefined pressure value. The data table can also be printed out through the mini printer.

Attributes:

- Multi-position design, more convenient and efficient (Please consult AT2E for other position request).

- Automation control ensures the high accuracy and repeatability.

- High quality stainless steel frame which is safe and durable.

- Superior controlling components ensures the accuracy and durability.

- Flexible position selection – each position can be controlled separately by system. Users can enable the positions (from 1 to 26) according to their test request.

- Automatic pressure compensation during the test process.

- Suitable for testing various size of bottle.

- Corrosion-resistant design

- Anti-explosion and clear observation window which is safe and easy to observe the sample status during a test.

- Various safety designs.